Leveling & transition profiles for door thresholds & floor coverings

With our transition profiles and compensation profiles, we offer an extensive selection of high-quality profiles made of aluminum or stainless steel, which we carry in various designs and colors. The transition profiles are optionally available with reliable self-adhesive, for screwing or with concealed slat dowels. The mounting material is of course already included in the scope of delivery.

- We offer aluminum transition profiles for door thresholds in various colors and designs

- We offer transition profiles for screwing or self-adhesive made of stainless steel, soft PVC and aluminum

- Height differences between floor coverings can be evened out with our leveling profiles

- Our self-adhesive aluminum transition profiles are ideal for non-floating floor coverings

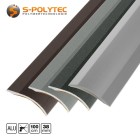

40mm Alu-Floorprofile (perforated)

from €8.01 /

from €8.01 /Incl. 19% Tax

40mm Alu-Floorprofile (self-adhesive)

from €8.91 /

from €8.91 /Incl. 19% Tax

50mm Alu-Floorprofile (self-adhesive)

from €9.88 /

from €9.88 /Incl. 19% Tax

40mm Stainless Steel-Floorprofile brushed (perforated)

from €8.98 /

from €8.98 /Incl. 19% Tax

40mm Stainless Steel Floorprofile brushed (self-adhesive)

from €9.88 /

from €9.88 /Incl. 19% Tax

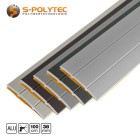

38mm Alu-Floorprofile (self-adhesive)

from €7.18 /

from €7.18 /Incl. 19% Tax

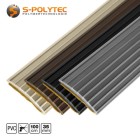

35mm PVC-Floorprofile (self-adhesive)

from €5.32 /

from €5.32 /Incl. 19% Tax

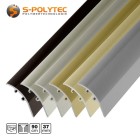

37mm Alu-Adjustmentprofile (slat dowel)

from €9.84 /

from €9.84 /Incl. 19% Tax

38mm Alu-Adjustmentprofile (self-adhesive)

from €9.88 /

from €9.88 /Incl. 19% Tax

Transition profiles from S-Polytec

Large selection ✓ Countless areas of application ✓ Also available in stainless steel ✓

Transition and adjustment profiles are among the final steps in renovation work, completing the project 100% and ensuring a visually appealing transition from one room to the next. However, these inconspicuous metal strips are much more than that. They prevent debris from accumulating in the gap between two adjacent floor coverings and conceal uneven edges on laminate, parquet or vinyl flooring. In addition to their visual appeal, adjustment profiles also reduce the risk of tripping.

Thanks to our wide range of colours and designs, we can offer the right floor profile for your floor, ensuring that your project is perfect and flawless down to the last detail. From profiles for secure screw fastening of floating laminate floors to designs with strong adhesive surfaces on the underside of the profile, which provide a closed surface without visible screws, there is something for every taste and every floor. And all this at an absolutely fair price-performance ratio.

We place great importance on quality and durability in our floor profiles.

Cheap products must be affordable, because poor quality often fails to meet expectations. However, this does not mean that good quality always has to be expensive. We use high-quality metal alloys made of anodised aluminium or stainless steel for our floor profiles to meet the highest demands and ensure uncompromising durability without breaking the bank.

Our product range for adjustment and transition profiles

- Self-adhesive 40mm aluminium transition profiles with smooth surface

- Perforated 40mm aluminium transition profiles with smooth surface for screw fastening

- Self-adhesive 50mm aluminium transition profiles with smooth surface

- Self-adhesive aluminium adjustment profiles for height compensation from 4mm to 11mm

- 40mm aluminium adjustment profiles for height compensation up to 17.5mm for concealed installation

- Flat aluminium floor profiles with coarse grooves, 2.5mm profile height and 38mm width

- Self-adhesive 40mm stainless steel transition profiles with brushed surface

- Perforated 40mm stainless steel transition profiles with brushed surface for screw fastening

- Self-adhesive 35mm transition profiles made of soft PVC with coarse grooves

- Transition profiles in silver, gold, bronze, Sahara, matt or polished stainless steel

- Floor trim in silver, metallic grey, metallic bronze or metallic anthracite

- Customisation profiles in silk matte colours or with a subtle metallic effect

Our extended range of transition profiles is available on request

- Aluminium and stainless steel transition profiles with self-adhesive backing up to 270cm in length

- Self-adhesive transition and compensation profiles in various wood finishes

- Various aluminium transition profiles in widths from 30mm to 100mm

- Reinforced transition profiles for high loads with 2.6mm profile thickness

- and much more

How to process transition and adjustment profiles?

Cutting The metal profiles can be cut to length very easily using a simple hacksaw with a metal saw blade. For the soft PVC profiles, sharp scissors or a knife with a stable base are sufficient. For perforated profiles, it looks much more attractive if they are shortened by half on both sides. This ensures that the holes closest to the edge are equidistant from the outer edge.

Drilling In principle, it is not necessary to drill the transition profiles, as they are either pre-drilled or equipped with a very reliable self-adhesive backing. However, if holes do need to be drilled for installation, an HSS drill bit is the perfect choice. A larger drill bit or a countersink can then be used to countersink the hole slightly to achieve a flush finish when using countersunk screws. We recommend marking the desired positions in advance with a centre punch so that the drill bit does not slip on the smooth surfaces and cause scratches.

Screw fastening Screwing is the safest method, especially for floating floor coverings or in outdoor areas where there can sometimes be significant temperature fluctuations. That is why we offer pre-drilled profiles in addition to self-adhesive ones. Of course, the profiles can also be screwed down with adhesive strips on the back, even if this is not really necessary. To do this, the profile must be drilled at the desired points and ideally countersunk with a countersink bit so that the screws do not protrude. We recommend small countersunk screws and suitable dowels for this purpose. The matching countersunk screws with dowels are of course included in the scope of delivery for our perforated profiles.

Adhesion The profiles are either screwed into the substrate using the screws supplied or are already equipped with a very strong adhesive backing. However, this does not mean that they cannot be bonded in other ways. With a mounting adhesive, for example a MS polymer, bonding succeeds extremely well. Depending on the elasticity of the adhesive, it is also possible to use the unperforated profiles outdoors or for floating floor coverings. It is important that the adhesive is suitable for both metal and the corresponding substrate. A solvent-based adhesive is definitely unsuitable here, as it cannot dissolve metal to achieve its adhesive strength.

Coating Coating with coloured adhesive film is no problem for metal floor profiles. It is even very easy on smooth profiles. However, it becomes a little more challenging with coarse or finely grooved profiles, as the film must be pressed into the grooves with a squeegee to ensure that it adheres well. This is much easier with a hot air gun set to a moderate temperature. It is important to note that the profiles must be completely clean to prevent dust and air pockets from getting trapped under the film.

Painting The anodised surfaces are very even and smooth and therefore do not provide optimal adhesion for paints. Light sanding with fine sandpaper creates significantly better surface adhesion for paints and primers. Sanding is relatively easy on smooth profiles, but more complicated on grooved designs. Before painting, the entire surface must be thoroughly cleaned of sanding dust and grease. Even fingerprints can impair the adhesion of the paint. A suitable primer that is suitable for anodised aluminium can be helpful in improving the adhesion of the paint. Plastic profiles with soft PVC slats, on the other hand, cannot be painted. The paint would peel off the surface of the plastic after a short time. Although a primer can increase the adhesion of the paint, the result will certainly not be satisfactory or long-lasting. In that case, you might as well save yourself the trouble.

What distinguishes transition profiles from adaptation profiles?

A transition profile is used to create a visual transition from one surface to another. This could be different floor coverings between two rooms, for example. It is important that the height of the surfaces is almost the same. This is the only way to ensure sufficient adhesion of the self-adhesive profiles. With perforated transition profiles, the tolerance range is slightly larger, but there are still limits. If the height difference is too great, the small countersunk screws cannot be screwed into the substrate at a right angle to the profile. This results in the screw head protruding. Holes in the socks cannot then be ruled out.

An adjustment profile, on the other hand, is not as suitable for transitions between surfaces of the same height, as a height difference is required here. This could be a transition from carpet to tiled flooring, or from laminate with impact sound insulation to a thinner, fully bonded design vinyl floor. Adjustment profiles therefore always specify a minimum and maximum value for height compensation. Within this range, self-adhesive adjustment profiles ensure excellent and permanent adhesion. If the minimum value is exceeded or not reached, the adhesive strips may not achieve sufficient contact with the substrate, which will have a negative effect on the durability of the bond. The socks are also at risk with screwed profiles, because the same applies here: if the screw is not screwed in straight, the head will not be flush with the profile surface.

Can transition profiles be used outdoors?

With the exception of PVC floor profiles, all our transition profiles are made of rustproof metal alloys, such as stainless steel or anodised aluminium, meaning that they can be used outdoors without any concerns. Neither moisture, standing water nor strong sunlight have any effect on the longevity of these high-quality profiles.

Nevertheless, some profiles are more suitable for outdoor use than others. This applies to all designs that have a self-adhesive backing. This is due to the thermal expansion of the installation surfaces and the profiles themselves, which is caused by temperature fluctuations between summer and winter (and vice versa). Such changes in length do not affect the profiles themselves, but they do affect the adhesive, as the adhesive is only partially elastic and can peel off in places over time due to constant expansion and contraction. With the perforated transition profiles, which are anchored to the substrate with screws and dowels, this risk is eliminated, so that all profiles are equally suitable for screwing in interior construction as well as for all outdoor applications. The same applies to compensation profiles in concealed installation with flexible lamella dowels.

Care and cleaning of transition profiles

Profiles used to transition between floors can, like the floor covering itself, become dirty over time from foot traffic or dust. Normally, routine household cleaning is sufficient, so that the profiles can simply be vacuumed with a vacuum cleaner, mop or robot vacuum cleaner. A standard cleaning agent suitable for floor coverings will not affect the surface of the profiles. As all transition profiles in our shop are made of corrosion-resistant material, there is no need to worry about rust forming due to moisture.

Especially with adaptation profiles with finely grooved surfaces, wiping in the opposite direction to the longitudinal direction can cause dirt to settle in the fine grooves over time due to the wiping water no longer being completely clean. This is particularly true when cleaning is carried out by a wiping robot without a rotating mop attachment, which merely brushes a damp microfibre cloth over the surfaces. However, such accumulations in the fine grooves can be easily removed with a damp cloth in the longitudinal direction, leaving the anodised surfaces shining like new. A soft cloth with a little water, soap solution or mild household cleaner is suitable for this purpose.

Never use scouring pads or coarse cleaning brushes to clean metal surfaces. This can leave visible marks on the surfaces. Sharp and highly concentrated cleaning agents are also not suitable for cleaning aluminium or stainless steel. Cleaners containing abrasives or solvents should also not be used to clean the floor profiles.

Disposal and recycling of transition profiles

Our adjustment profiles are made from solid, high-quality metal alloys that are extremely easy to recycle. It would be a shame to simply throw the profiles or sections into the residual waste. Instead, it would be better to take them to a recycling centre. The scrap metal collectors who drive around residential areas in their vehicles are grateful for even small, inconspicuous quantities. Proper disposal saves resources and thus also protects the environment. Usually, there is no charge for disposing of metals, and for larger quantities, you may even receive a few pounds for scrap metal.

The only exception is our self-adhesive floor profiles made of soft PVC. Sections, as well as old profiles that are no longer to be used, can be disposed of in small quantities with the residual waste. Larger quantities, which are unlikely to accumulate in the case of our floor profiles, can be taken to a recycling centre for proper disposal. PVC plastic does not belong in the yellow bin, as this plastic mixes with other plastics during the recycling process, which can have serious consequences for the extrusion systems and sometimes cause severe damage.