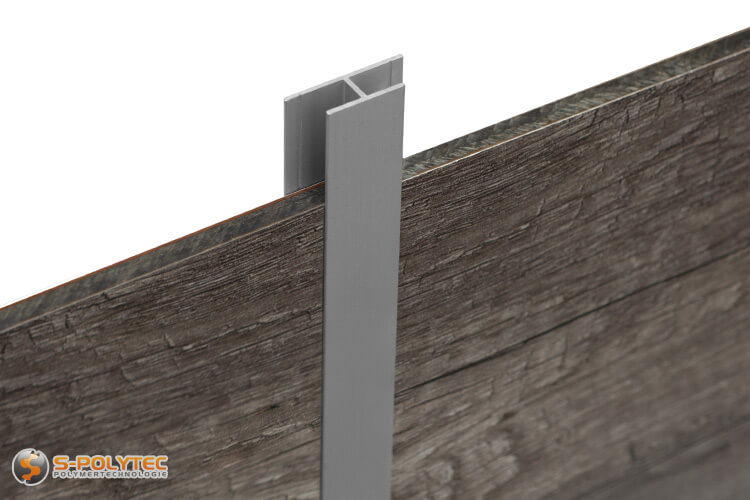

Aluminium H-profile silver (anodised)

Our silver-coloured aluminium H-profiles are suitable as connecting profiles for covering gaps between panels, wall and floor coverings. The profiles can be used indoors and outdoors without hesitation thanks to manufacture from corrosion-resistant, anodised AW 6063 T6 aluminium in a solid construction.

✓ High quality EN AW 6063 T6

✓ Anodised surfaces

✓ Corrosion resistant

✓ For indoors and outdoors

✓ High inherent rigidity

✓ Smooth surfaces

The silver anodised connecting profiles are optionally available with a 3mm, 6mm or 8mm clamping range at favourable graduated prices.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium H-profiles in aluminium silver as connecting profiles

Anodised surfaces ✓ Also for outdoor applications ✓ Smooth surfaces ✓

Our silver aluminium H-profiles with a clamping range of 3mm, 6mm or 8mm are suitable as connecting profiles for two panels of the corresponding thickness. Depending on the version, the profiles are ideal for our aluminium composite panels and acrylic glass panels, or also facade panels made of HPL, which we offer in a wide range of colours and decors in cut-to-size. The filigree profiles with an excellent surface quality are easy to process and can be shortened without any problems if required. To ensure that the profiles are not affected by weathering, we only use anodised aluminium in an EN AW 6063 alloy for the H profiles, which is characterised by very good corrosion resistance. This means that the profiles can be used indoors and outdoors without hesitation.

Due to the low profile thickness of only 1.1mm, further processing of the H-profiles is extremely easy. With a standard length of 2000mm, cutting to the required size is one of the most common processing methods. This can be done with an angle grinder, a cross-cut saw or a simple hand saw. A complete 2-metre length weighs between 276 grams and 306 grams, depending on the thickness. Despite the very low weight, which is also due to the low profile thickness, the H-profiles offer a very high stability and inherent rigidity, which contributes to a considerable increase in the bending rigidity of the panels, especially with flexible panels or low panel thicknesses.

NOTE: Our aluminium H-profiles are available in the clamping ranges 3mm, 6mm and 8mm in a length of 2000mm. In addition, we also offer U-profiles as edge trim, as well as outer corner profiles for connecting panels at right angles in the same clamping ranges made of anodised aluminium in silver at favourable prices.

Properties of the silver anodised aluminium connecting profile

The aluminium H-profiles are made of a high-quality EN AW 6063 T6 aluminium alloy, which is also known colloquially as architectural aluminium. This alloy is already characterised by very good corrosion resistance even without additional surface finishing, but is further protected against corrosion by environmental and weathering influences through anodic oxidation. In addition, the silver surface acquires a perfect, consistent gloss level that would not be uniformly pronounced on extruded aluminium without this form of surface refinement. This process, known as anodising or anodising, ensures that the profiles can be used outdoors without hesitation. This makes the H profiles ideal for bridging gaps in facade cladding, balcony surrounds and glazing for patio roofs and carports, effectively preventing cold bridges and moisture penetration through rain.

The connecting profiles, whose cross-section is reminiscent of the capital letter H, are often also referred to as double-T profiles and are available in our online shop in 2000mm lengths. The profile width on the front side is 17mm for all versions. The rear side with the widened mounting surfaces, on the other hand, has a width of 26mm. Due to the smooth, silver surface of the profiles, the rear side can also be used as a visible profile side without hesitation. Whereas the profile width on the front and rear side, as well as the standard length of 2000mm (plus 5mm plus tolerance) is identical for all H-profiles, the profile depth varies depending on the clamping range and is 5.7mm for the 3mm profile, 8.7mm for the 6mm profile and 10.7mm for the 8mm profile. These dimensions result from a double profile thickness of 1.1mm and the maximum clamping range, which is always 0.5mm more than the specified clamping range for all profiles. This ensures that panels with higher manufacturing tolerances in relation to the panel thickness can still be inserted into the profile without any problems. The manufacturing tolerances according to the EN 12020 standard (extruded precision profiles made of EN AW-6060 and EN AW-6063 alloys), on the other hand, are extremely low and are subject to strict quality controls.

Specific data of the different profile sizes

- Alu H-Profile 3mm: Clamping range: max. 3.5mm, profile depth outside: 5.7mm, weight: 138g/m

- Alu H-Profile 6mm: Clamping range: max. 6.5mm, outer tread depth: 8.7mm, weight: 147g/m

- Alu H-profile 8mm: Clamping range: max. 8.5mm, profile depth outside: 10.7mm, weight: 153g/m

Application and assembly of the silver aluminium H-profiles

Anodised aluminium is characterised by outstanding corrosion resistance and significantly improves the appearance of the surface of untreated aluminium. The H-profiles, which are used for cladding between two panels, can be used outdoors without hesitation due to their outstanding corrosion resistance. The high-quality, silver surface is not only ideal for silver aluminium composite panels or HPL panels in silver-grey, but also provides an attractive contrast for cladding panels and floor coverings in wood decor and catches the eye with intense colours and darker shades of grey. This enhances the appearance at the butt edges of the panels in a simple but effective way. Particularly in outdoor areas, or when used in damp rooms, the edge covering has the advantage that the use of the H-profiles prevents moisture from getting into the masonry through the gaps between the adjoining panels, thus better protecting the structure from moisture damage.

TIP: The silver anodised aluminium H-profiles are currently only available in the standard length of 2 metres. A standard hand saw with a metal saw blade is sufficient to shorten the connecting profiles to the desired length. A cross-cut and mitre saw with a suitable saw blade can be used to cut the profiles extremely precisely, especially if they are to be mitred.

In most applications, it is sufficient to clip the profiles onto the cut edge of the panel. Depending on the manufacturing tolerance of the panel manufacturer, the clamping force of the profiles is sufficient to ensure a secure hold without the profiles slipping. However, in the case of glass or plastic panels with a very even smooth surface, it may be necessary to seal the profile with a silicone sealant or bond it with an MS polymer. We have taken this into account in the design of all our optical profiles and have incorporated a small recess on the mounting surface of the profile, which leads to better adhesion of the bonding. In addition, the filigree groove with a radius of 0.25mm provides a perfect guide when applying the adhesive and sealing compound.

Application examples for aluminium H-profiles

- H-profiles are suitable for connecting panels of the appropriate thickness - both horizontally and vertically

- The H-profiles can be used to bridge gaps in facade cladding in order to close cold bridges

- The straight profile covers and visually straightens unclean cut edges of adjoining panels

- The silver H-profiles serve as an inconspicuous connection of roofing made of glass, acrylic glass or polycarbonate

- The profiles are perfectly suitable as a visual connecting element for different wall and floor coverings

Technical data of the aluminium H-profiles

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Silver anodised

- Colour: Aluminium silver

- Profile shape: H-Profile (Connection profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength: 1,1mm

- Visibility: 17,0mm

- Profile width: 26,0mm

- Mounting surface: 12,45mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID AL-HP-000P0000 Standart Length 2000 Delivery Time Dispatch within 2-3 working days Material Aluminium anodised Profile type H-Profile Clamping range varies Color Metallic Color accuracy No information available Color designation Aluminium silver - Reviews

- Attachments