HPL panels cut to size – incl. colour-matched installation accessories

- Free samples

- Precision cutting & CNC milling according to your drawings on request

- Colour-matched installation accessories

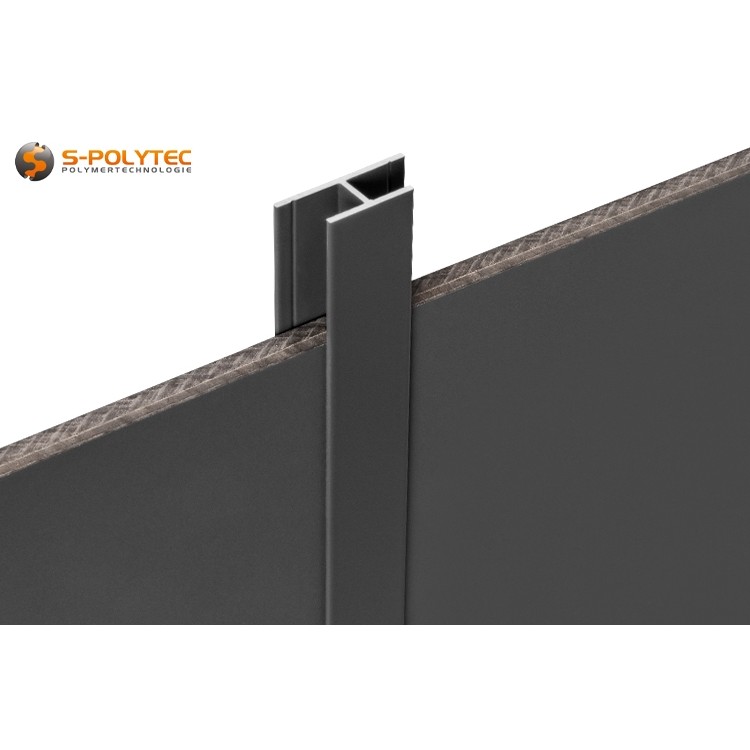

- Colour-matched H, U and corner profiles made of aluminium

- Aluminium substructure as a complete system solution

HPL sheets anthracite (RAL7016)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

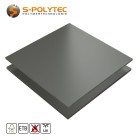

HPL panels dusty grey (RAL7037)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets traffic white (RAL9016)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets vintage look (oak white)

from €74.11 / m2

from €74.11 / m2Incl. 19% Tax

HPL sheets light grey (RAL7035)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

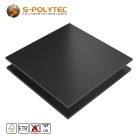

HPL panels jet black (RAL9005)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets wood decor (dark ash)

from €74.11 / m2

from €74.11 / m2Incl. 19% Tax

HPL sheets silver gray

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

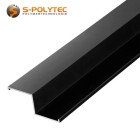

Aluminium Z-Profiles Black (anodised)

from €30.40 / pcs

from €30.40 / pcsIncl. 19% Tax

Aluminium V-Profiles Black (Anodised)

from €45.09 / pcs

from €45.09 / pcsIncl. 19% Tax

VHM facade panel drill

from €39.27 / pcs

from €39.27 / pcsIncl. 19% Tax

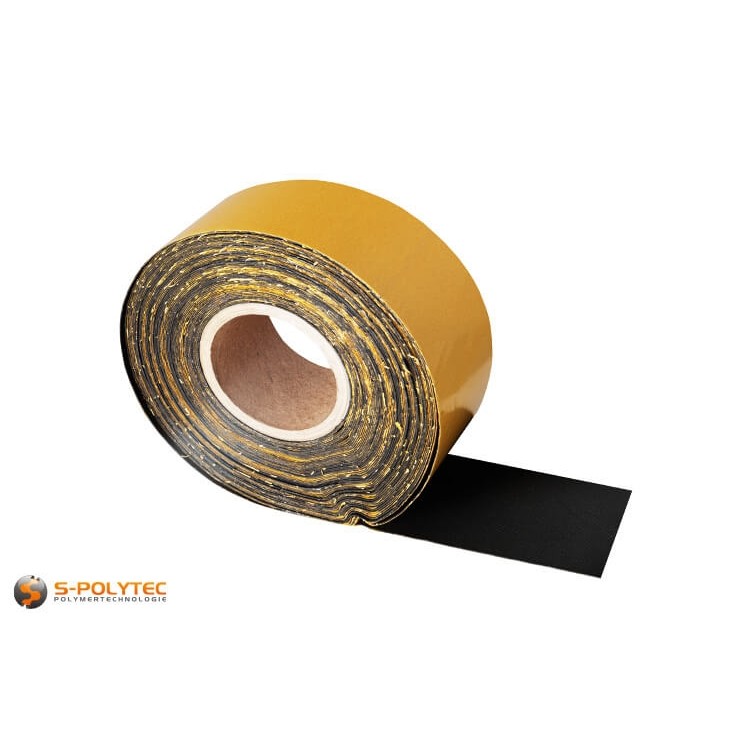

EPDM sealing tape 70mm - 25m roll (self-adhesive)

from €47.60 / pcs

from €47.60 / pcsIncl. 19% Tax

Mounting accessories for HPL panels – our product recommendations

Matching accessories for fast and clean installation of HPL panels – direct links to the products.

Tip: Swipe (mobile) or use arrows (desktop) – the slider pauses while you interact.

HPL panels cut to size – FAQs, accessories & installation

Here you will find concise answers about HPL cut-to-size panels, matching accessories and key installation notes (thermal expansion, expansion joints, rear ventilation).

How do I install HPL panels correctly (consider thermal expansion)?

HPL has a comparatively high thermal expansion. Therefore, the panels must be installed without constraint, so they can expand/contract – otherwise bulging or stress cracks may occur.

- Fixed point + sliding points: One fixing point is executed as a fixed point; all other points as sliding points (oversized hole).

- Example drill size: With a 4 mm screw, the sliding-point hole is approx. 8 mm.

- Do not clamp: Set screws/rivets so the panel is guided, but not under tension.

- Plan joints: Leave sufficient gaps to adjacent components/panels (expansion joints).

- Rear ventilation: Install ventilated façades to avoid heat build-up and warping.

Rule of thumb: Do not drill too close to the edge and protect panel edges with profiles/covers.

How can I create attractive corner joints?

Visually clean corner joints for HPL panels are best achieved with aluminium profiles – neat, stable and durable. This applies to visible surfaces indoors (e.g. furniture, wall cladding, partitions) as well as to applications with higher loads, moisture or frequent cleaning. The key is that profile geometry, panel thickness and fixing method match – then you get a precise corner with an even joint and long-lasting hold. Aluminium profiles protect the edge, ensure clean lines and stabilise the connection. With profiles you can realise defined shadow gaps or flush transitions – depending on whether you want the corner to stand out or look as “invisible” as possible.

Fixing: bonding, screwing or combined

In practice, there are three proven options:

- Bonding: very clean visually, no visible screw heads. Ensure clean, degreased surfaces and apply pressure during curing.

- Screwing: robust under dynamic loads. Correct pre-drilling and stress-free seating are crucial.

- Bonding + mechanical securing: often ideal for commercial projects, combining appearance and stability.

Which HPL panels can I order online?

Choose 6 mm or 8 mm, configure your millimetre-precise cut (format tolerance +/-1 mm) and – depending on the product – you can also request custom CNC routing (e.g. cut-outs, drill holes, contours up to 3 x 2 metres).

Why do HPL panels on façades need rear ventilation?

For façade applications, HPL panels should be installed ventilated. Rear ventilation helps to balance temperature and moisture differences. This reduces the risk of deformation and keeps the construction stable long-term.

A suitable substructure (e.g. timber/aluminium) with a defined distance to the wall is important, so air can circulate.

Which is better: screws or rivets?

That depends on the substructure:

- Timber substructure: usually screws (e.g. facade screws / balcony screws).

- Metal substructure: often rivets (facade rivets) or suitable screw solutions.

For a consistent look, fixings are available in matching colours to the panel and profiles.

Which drill bit is suitable for HPL?

HPL is hard – for clean drill holes (low risk of chipping), a suitable drill bit is recommended, ideally a dedicated solid carbide (VHM) drill bit.

Matching product: Solid carbide drill bit for façade panels

Do you offer a sample service?

Yes – free sample shipping. This lets you check décor/colour in advance and then choose matching accessories (profiles, screws, rivets) in coordinated colours.

What is the delivery time?

We stock HPL panels and accessories. Your order is usually dispatched within 2–3 working days. Shipping providers typically need 1–2 days.

Is collection in 47559 Kranenburg possible?

Yes – collection is possible. With collection, larger formats can also be ordered (up to 4200 × 1860 mm).

What are HPL panels?

HPL panels are particularly robust decorative panels commonly used for exterior façades, balcony cladding or furniture making. HPL stands for High Pressure Laminate.

During manufacturing, multiple layers (kraft papers, fibres and resins) are pressed together under high pressure and heat to form a solid panel. The many layers create the typical, often dark core.

The surface is created using a decorative paper that determines the design. That is why HPL is available in many colours and decors: solid colours as well as wood, stone, concrete or rust looks.

Many HPL panels are suitable for outdoor use because they withstand moisture, UV radiation and temperature fluctuations very well.