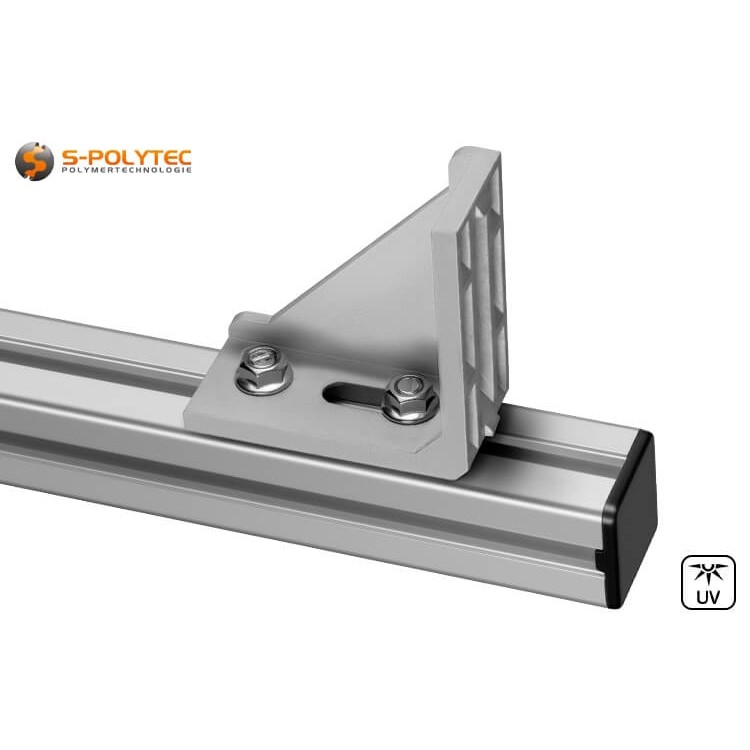

90° Heavy-duty angle bracket for construction profiles

The reinforced 90° mounting brackets made of corrosion-resistant die-cast aluminium for construction profiles are suitable for particularly stable angle connections of constructions in indoor and outdoor areas.

✓ Corrosion-resistant die-cast aluminium

✓ Extra-reinforced design

✓ Suitable for 8mm groove width

✓ For stable connections

✓ Anti-twist thanks to slot bars

✓ For indoor and outdoor use

The reinforced heavy-duty angles with 90-degree angles for construction profiles are available in 30mm and 40mm widths.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €2.84/ pc. (Base Price €2.84/ pc.)

- from 20 Items €2.80/ pc. (Base Price €2.80/ pc.)

- from 50 Items €2.75/ pc. (Base Price €2.75/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

90° Heavy-duty angle bracket – for particularly stable angle connections

High-quality die-cast aluminium ✓ With slot nuts ✓ For cylinder head screws ✓

Our large 90° mounting brackets made of solid die-cast aluminium are available in two sizes for construction profiles with a width of 30mm or 40mm and 8mm grooves. These profile versions are often used for load-bearing constructions that have to withstand different types of loads. The heavy-duty connectors with a large mounting surface and one-sided angle reinforcement are ideal for such conditions. Die-cast aluminium is characterised not only by its low weight and enormous rigidity, but is also corrosion-resistant, so that even moisture, rain and UV radiation do not affect the durability and appearance of the constructions.

The reinforced angle connectors have large mounting surfaces with two elongated holes each and slot webs on the underside to guarantee maximum security against twisting of the constructions and are therefore the perfect choice in mechanical engineering for industrial plants that are exposed to high mechanical loads due to movement or vibration.

NOTE: To mount the brackets, you will need four cylinder head screws with matching slot nuts or hammer head screws and flange nuts for 8mm slot width. The fasteners are also available in the shop in any quantity, so that the amount can be purchased as needed without fixed packaging units.

Properties of our heavy-duty brackets made of die-cast aluminium

Our heavy-duty angles are made of high-quality die-cast aluminium with a high material thickness to withstand the heavy loads without hesitation. The die-casting process has many advantages. It is cost-efficient, enables rapid series production and guarantees very precise dimensional accuracy of the angles. Furthermore, the material is light and extremely corrosion-resistant, so that the brackets can be used for all constructions, even under the most adverse weather conditions and permanent humidity. Another advantage, which can be attributed to the die-casting process, is the semi-gloss surface in silver-grey with a slight metallic effect.

To ensure that the profile connections are exactly at right angles, each heavy-duty angle bracket has a one-sided massive reinforcement that guarantees angularity even at high loads. The 30mm angle has a wall thickness of 3mm. The side reinforcement of the 40mm heavy-duty angle is an incredible 4.5mm thick. The construction is safe even under high mechanical stress. It does not matter whether it is a sensitive industrial plant where dimensional accuracy is of great importance, as is the case with our CNC portal milling machines. Massive heavy-duty angles also offer the perfect combination of safety and load capacity for constructions for floors, staircases or roofs. Additional grooved webs on the underside, as well as the elongated holes for mounting on the profile, further increase the angle's resistance to twisting.

NOTE: The solid mounting brackets in a reinforced design are provided with two elongated holes on each side for mounting. One of these is longer than the other. These are suitable for mounting with cylinder head screws with slot nuts or hammer head screws with flange nuts. However, we strongly advise against mounting with countersunk head screws, as these do not provide sufficient support for load distribution due to the conical head shape.

Specific data of the reinforced mounting brackets

- 90° heavy-duty connector 30x55mm: Dimensions (WxLxH): approx. 30x55x55mm, mounting holes: 18.5x6.8mm and 9.5x6.8mm, weight: 35g

- 90° heavy-duty connector 40x90mm: Dimensions (WxLxH): approx. 40x90x90mm, mounting holes: 32.5x10.4mm and 12.5x10.4mm, weight: 111g

Installation and use of heavy-duty couplers

Installing angle connectors is relatively simple. Depending on whether they are to be fastened with hammerhead bolts or socket head screws, the procedure and the necessary tools differ slightly. The easiest way is to insert a hammerhead bolt or a sliding block into the slot, to guide the bolt through the smaller slot and fix it lightly. In doing so, you roughly slide the bracket to the desired position. Finally, the second profile is connected to the heavy-duty angle bracket in the same way. Now the final and precise alignment can be done and the screw or nut can be tightened with the appropriate Inbus® key or socket. The large slot is significantly longer so that the hammerhead screw can be inserted through the hole into the slot, turned and tightened with a nut against the profile.

WARNING: Depending on the design of the slot nut or hammer screw, the second fastening for the larger slot must also be inserted into the slot beforehand before the bracket is screwed on.

When screwing, care should be taken to ensure that both groove webs run within the profile groove to ensure that the angle connection is protected against twisting. The exact alignment of the profiles can be checked and corrected as long as the screws have not yet been fully tightened. To change the position along the profile groove or for precise alignment, a spirit level or a goniometer can be used to loosen the screws slightly at any time. This is the advantage of construction profiles, which contribute to the flexible systems being so popular in countless industries and trade sectors.

TIP: The mounting brackets for heavy-duty connections have pronounced groove webs on the mounting surface to prevent the bracket from twisting. This means that the brackets can only be mounted along the groove and are not suitable for direct wall mounting or in furniture construction with wood or wood-based panels.

Heavy-duty angles for construction profiles are used wherever stable connections are to be expected due to high loads. These include storage systems and heavy-duty racks where the load results from an increased loading capacity. However, not only the load-bearing capacity plays a role, but also the rigidity of a construction due to movement stress. In plant construction and robotics in particular, the solid angle connectors are used for base frames that can easily withstand mechanical loads. These can be production robots in large-scale industries, as well as tables for laser and CNC systems, where even small changes in the design can have a massive impact on the accuracy of the manufacturing processes.

The high rigidity and load-bearing capacity that comes with the use of large mounting brackets is, of course, also very good for load-bearing outdoor structures. These can be stair structures, fall protection on balconies or on flat roofs, as well as floor substructures in stage construction. Even greenhouses, carports, patio covers or container parking spaces are no problem and can withstand wind, rain and snow without difficulty. The heavy-duty angles are particularly convincing under such loads, whereas the small mounting angles are very well suited for additional reinforcing struts in large constructions.

Examples of applications for reinforced mounting brackets

- The solid construction of the brackets makes them particularly suitable for connecting construction profiles in a stable manner

- The 90° angles are ideal for medium-sized constructions as a roof or covered parking space in outdoor areas

- When building stairs from construction profiles, the large heavy-duty brackets ensure the necessary stability

- The large angles allow for stable basic constructions for systems with high mechanical loads

- The solid heavy-duty connectors are ideal for constructing heavy-duty racks with construction profiles

Technical data of the 90° mounting bracket

- Material: \Aluminium die casting

- Colour: Silver

- Angle: 90°

- Height: 55mm and/or 90mm

- Width: 30mm and/or 40mm

- Mounting holes: Longitudinal hole

- Ø Screws: 6mm and/or 8mm (max. 10mm)

- Weight: 35g and/or 111g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID BFW-0000-V Delivery Time Dispatch within 2-3 working days Property 90° Heavy-duty angle bracket Material Aluminium die casting Color Silver - Reviews

- Attachments

You may also be interested in the following product(s)

Aluminium construction profile 20x20, groove 6 silver (anodised)

Aluminium construction profile 30x30, groove 8 silver (anodised)

Aluminium construction profile 40x40, groove 8, silver (anodised)

Hammer screws for construction profiles

Countersunk head screw made of carbon steel (nickel-plated)

Flange nuts (galvanised steel)