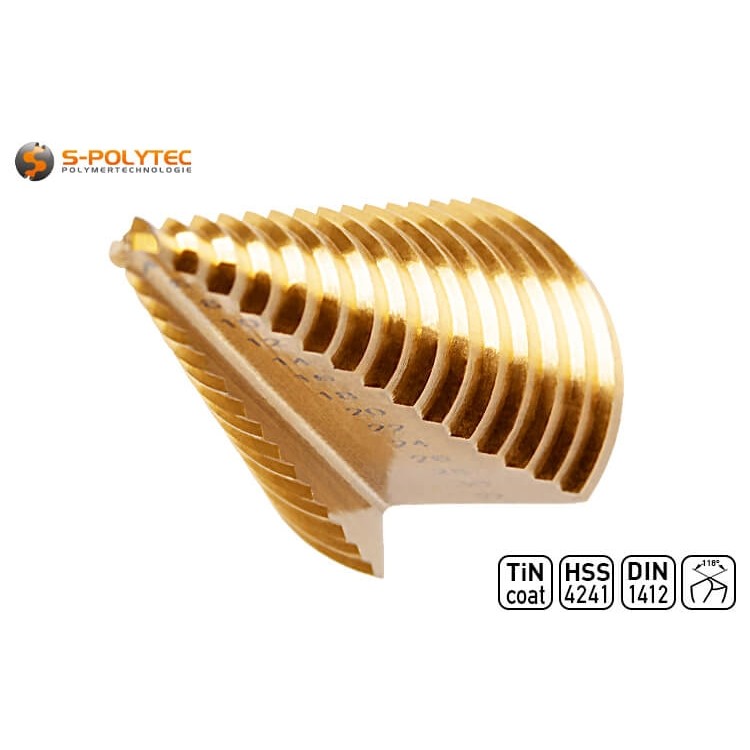

TiN-HSS step drill 4mm-32mm (DIN 1412C)

The 4mm - 32mm step drill bit from Högert, made of HSS steel with a titanium nitride coating, is a universal drilling tool for drilling and expanding precise holes in aluminium, stainless steel, plastic, wood and much more up to 4mm thick.

✓ Made from premium steel

✓ With titanium nitride coating

✓ For precise hole drilling

✓ Two straight cutting grooves

✓ Drilling in 15 grades

✓ Up to 4mm material thickness

The high-quality TiN-HSS step drill bit enables precise hole drilling in 15 sizes between 4mm and 32mm.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€9.90 / pc.

0,1650 kg / pc.

All prices include 19% VAT.

- Description

Högert step drill 4mm - 32mm made of TiN-HSS steel

Titanium nitride coating ✓ Enormous durability ✓ With centre point ✓

Our high-quality Högert 4-32mm step drill bit made of HSS steel is a true all-rounder and perfect for countless technical or DIY jobs with the highest quality standards. The titanium nitride-coated drill bit is available in 15 different sizes with precise increments. The individual increments have a distance of 4mm to the next larger diameter and increase the bolt circle by 2mm each time. This makes it possible to drill holes and enlarge holes between 4mm and 32mm in diameter up to a material thickness of 4mm. The drill bit is self-centring for the most precise holes possible. This not only ensures exact holes with high roundness, but also enables easy centring in hard materials, even without pre-punching the surface. The HEX 1/4" inch drive is suitable for any standard bit holder and can also be used in any conventional keyless chuck.

The titanium nitride coating not only gives the special drill its golden colour but also contributes to a significantly increased heat resistance due to its higher hardness. In combination with the improved corrosion resistance, the service life of the high-quality drill bit is significantly extended. The smooth surface ensures less friction between the material and the drill. The double cutting groove also helps to reduce heat build-up during drilling, which is also beneficial when drilling plastics.

Properties of the TiN-HSS steel step drill

A step drill owes its name to the step-like gradations from the smallest to the largest drilling circle. In the case of our HSS steel drill, the smallest drill hole diameter is 4mm and increases in 15 steps of 2mm each until the largest diameter of 32mm is reached. This means that the drill can be used for holes of 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm and 32mm. The sizes of the respective gradations can be easily read on the side of one of the two cutting grooves thanks to a laser engraving. The individual graduations with a step angle of 90° are straight in contrast to a conical drill bit, each with a height of 4mm. This means that precise holes can be made at right angles to the material surface. However, this is limited to 4mm because if this depth is exceeded, the next step is reached with a diameter increased by 2mm. Thanks to the ¼ inch hex receiver, the drill can be used in any standard bit receiver without any problems. The length of the hexagonal drive is sufficiently dimensioned at 25mm to clamp the tool directly in the chuck of a cordless screwdriver or a power drill.

The step drill is made of high-quality high-performance high-speed steel - HSS for short. The drill is also titanium nitride coated for optimised durability, which also gives the drill its typical golden colour. However, the colour is inconsequential compared to the extremely high hardness and significantly lower friction. This results in a much higher wear resistance, which ultimately also affects the service life of the step drill, which is three to four times longer than that of uncoated drills. The lower friction enables higher cutting speeds, as less heat is generated. The heat resistance of TiN-HSS steel is 600°C and thus significantly higher than that of ordinary tool steel or HSS steel. This also allows for higher speeds without the risk of the drill bit or cutting groove overheating. This is particularly noticeable when drilling in alloyed steels. When drilling plastic, the speed should be kept very low anyway, otherwise the plastic could soften. However, the two very large cutting flutes ensure very good cooling and drill chip removal, so that the heating is lower than with standard drills. The drill bit with two cutting edges also has a point angle of 118°. This is self-centring, so that precise drilling with the highest precision can be carried out even without pre-punching.

Use and handling of a step drill

A simple cordless screwdriver is an excellent choice for using a step drill. Of course, you can also use a power drill, as long as it has a keyless chuck and the impact drilling can be deactivated. A hand screwdriver with a bit holder is even suitable for deburring, because just a few turns with very little force are enough here. Much more important than the tool used to operate the step drill is the choice of speed at which you drill. Although it is made of high-alloy high-speed steel with a titanium nitride coating that reduces friction, increasing the speed automatically leads to a higher heat development. Depending on the material, this has different effects. When drilling hard metal alloys such as steel or stainless steel, the high friction can cause the cutting grooves to overheat, causing the drill bit to dull and, in the worst case, become unusable. However, the risk can be significantly reduced by using a special coolant or drilling paste. With plastics, especially with thermoplastics, excessive heat causes the drill chips to melt onto the edge of the drill hole. This is difficult to remove and, in the worst case, can even cause cracks or fractures in the plastic. The only thing that helps here is a significantly lower speed, which, however, is very easy to adjust on most cordless screwdrivers.

A step drill is often confused with the similar-looking taper drill and also incorrectly named. However, there are some differences between the two drill types that are very important when using them. The taper drill owes its name to its conical shape with a continuous cutting edge, the diameter of which increases evenly from the tip to the rear end. This allows the hole size to be varied as desired. However, it is not possible to drill straight holes. This may not have any effect on very thin sheets of metal or wood or plastic panels, but with increasing material thickness, the conical hole drilling sometimes becomes clearly noticeable. The step drill, on the other hand, is also conical in its basic form, but the cutting edge is clearly stepped, so that fixed diameters are created in the holes. In this way, our step drill can be used to drill 15 different sized holes with a diameter of 4mm - 32mm in a step size of 2mm.

Step drills are ideal for a range of applications. On the one hand, they can be used as a replacement for a conventional drill bit when drilling wood, metal or plastic. A step drill is particularly useful when several precise holes of different sizes are needed without having to change the drill bit. The disadvantage, however, is that you are limited to a material thickness of 4mm, because after 4mm the next larger step with a 2mm larger diameter already follows. To do this, the countersink drill bit, like any other drill bit, is stopped with the centre point at the marked position and drilled with light pressure and an adjusted speed until the desired step is reached, the diameter of which can be read laterally on one of the cutting grooves. Thanks to the so-called auto-deburring, the automatic deburring and smoothing of the edges during drilling, a further operation with a countersink and deburring tool is no longer necessary and makes manual edge processing of the drill hole redundant.

Another feature is the widening of holes. Especially in thin steel sheets, it is almost impossible to enlarge a hole with a diameter of 4mm, 6mm or 12mm by a few millimetres without the drill jamming. A step drill is perfect for such a task and is inserted into the hole until the corresponding step is reached. Drilling should always be carried out at the necessary speed with light pressure and continued until the hole size has reached the desired diameter. The fact that the drill bit is always positioned exactly in the centre of the existing hole, thanks to the individual steps, ensures perfectly circular holes. The fine increments also help to ensure that the drill does not jam at the edges of the hole, which could cause the plate to break when working with brittle, fragile materials such as PVC or acrylic glass. Even when enlarging drill holes, additional deburring is no longer necessary, since the edge is automatically deburred in such applications as well.

The third application is deburring holes. Here, too, you are not limited to a material thickness of 4mm. For example, a conventional HSS drill bit could be used for a thicker steel plate, or a wood drill bit for a table or worktop, to drill the hole and then the step drill is clamped into the drill chuck and guided into this hole. One or two rotations are usually enough to remove the burr. This method can also be used to create a chamfer or a slight countersink in the drill hole so that screw heads are better aligned with the surface.

NOTE: It is recommended to wear protective goggles and gloves when using a drill bit to protect against possible splinters.

The step drill bits are an extremely practical multipurpose solution, especially for tradespeople, and are valued by a wide range of trades for very similar reasons. Electrical installers like to use the drill bit with the different gradations for cable ducts of various cable diameters in control boxes, junction boxes and cable ducts. It is used in a similar way in the construction of hot and cold water or heating pipes. It is also used in metal construction, as well as in equipment and plant construction. Here, a step drill is used to drill through steel or aluminium sheets and to adjust the drilling circle to the desired diameter. These may be mounting holes for screw connections in the metal sheets, feed-throughs for control cables and compressed air hoses, but also for the subsequent attachment of buttons, switches, dials or status LEDs (e.g. the standby LED) at the drilled points. Drilling out small holes and deburring sharp-edged holes is a common task in any trade, for which a step drill or taper drill is used.

In the household, a step drill can also be very useful in a variety of ways. In addition to the applications already mentioned, which of course also help to ensure proper cable management in the home office, the step drill is suitable, for example, for drilling or widening the hole for mounting the tap in the sink. This is often necessary when retrofitting a tap with a pull-out head. In drywall construction, the step drill bit is perfect for laying cables and pipes through the stud frame. Although these usually already have prefabricated openings that can be easily bent open, not all manufacturers offer this convenience. A step drill bit is also a very good choice for retrofitting reversing cameras or parking distance control sensors, as the diameters vary depending on the manufacturer and brand. This requires a good technical understanding, but for the small holes in the body, a little manual dexterity, a cordless screwdriver and a step drill bit are enough. Less demanding, but no less practical, is its use for adjusting cable glands in wall and ceiling lights, drilling drainage holes in plastic plant pots or for ventilating plastic terrariums. Our golden step drill is also ideal for such tasks.

Examples of use for step drills with straight cutting flutes

- Electrical installers use step drills for cable penetrations in control boxes and cable ducts

- A step drill is a precise and easy way to enlarge drill holes in metals

- The step drill is also suitable for deburring existing holes in plastic or metal

- The step drill bit can be used to retrofit reversing cameras or parking sensors to a motor vehicle

- Plumbers use the drill bit to create precise holes for pipe penetrations

Technical data for our TiN-HSS step drills

- Drill type: Step drill

- Material: High-performance high-speed steel (HSS)

- Coating: Titanium nitride coating (TiN)

- Ø Drill: From 4.0mm to 32.0mm (15 levels))

- Execution: Profile ground

- Polish: Crosscut

- Peak angle: 118°

- Norm: DIN 1412

- Cutting groove: Double, straight

- Spiral length: Max. 4mm per step

- Total length: 102mm

- Recording: Bit recording (HEX 1/4")

- Direction of rotation: Clockwise

- Weight: 175g

WARNING: It is generally possible to use an impact drill, but it is important to note that the impact function must be deactivated before drilling so that the drill bit or cutting grooves are not damaged.

- Additional Information

Additional Information

Product-ID DRL01 Delivery Time Dispatch within 2-3 working days EAN/GTIN 5902801341595 Material High-performance high-speed steel (HSS) Drill size No Ø Bore From 4.0mm to 32.0mm (15 levels) Ø Schaft 6,0 mm Take-up Shank ¼ inch drive (6.35mm) Overall length 102 mm Spiral length Max. 4mm per step Spiral type Step drill Point angle 118 Degree Direction of rotation Clockwise Weight 0.1650 - Reviews

- Attachments