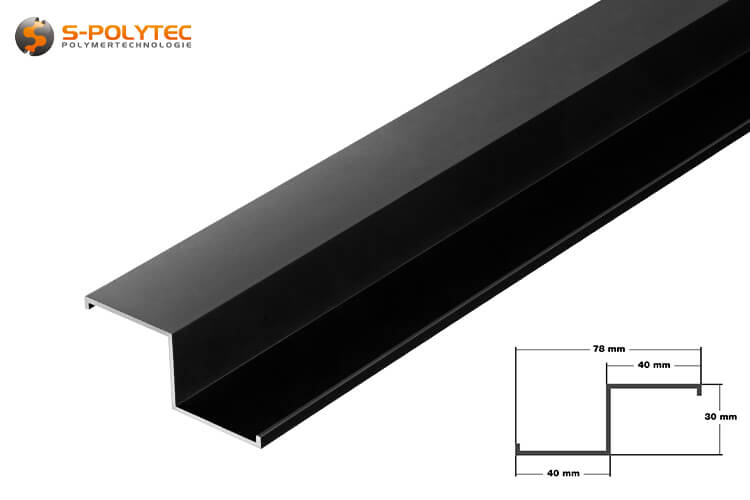

Aluminium Z-Profiles Black (anodised)

Our black anodised aluminium Z-profiles are characterised by outstanding corrosion resistance and can be used both as end profiles and as intermediate profiles for substructures of facade cladding.

✓ Black anodised aluminium

✓ Corrosion-resistant

✓ Enormously torsionally stiff

✓ High load capacity

✓ Maintenance free

The aluminium facade profiles with a length of 2000mm are available at favourable graduated prices.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Black anodised aluminium Z-profiles for facade panels

Corrosion-resistant ✓ AW EN 6063 T6 aluminium ✓ High load-bearing capacity ✓

Our Z-profiles made of black anodised aluminium are available in the standard length of 2000mm at favourable graduated prices. The profile depth is 30mm. The total width of the Z-profile is 78mm, with both support surfaces having a width of 40mm, in order to fix the profiles to the wall or to screw or rivet the facade panels to the profiles. With a thickness of 2mm, the Z profiles made of solid AW EN 6063 T6 aluminium have a very high load-bearing capacity, which also enables the installation of heavy facade panels, such as HPL panels or fibre cement panels.

The Z-profiles are used for the assembly of facade panels on the outer sides as an end profile of the substructure. In addition, Z-profiles are excellent as intermediate profiles for mounting larger cladding panels where fastening is required within the panel surfaces.

NOTE: Our black anodised profiles are not pre-drilled to ensure maximum flexibility when mounting the facade panels. Drill holes for wall fastening or for riveting the panels, for example with our facade rivets, can be easily made with conventional HSS drills.

TIP: For cutting the profile to size, we recommend a chop saw or jigsaw with a metal saw blade.

Properties of the aluminium Z-profile black (anodised) for substructures

Our black Z profiles are made of anodised aluminium in a high-quality AW EN 6063 T6 alloy, which is characterised by absolutely outstanding corrosion resistance due to the anodising process. During anodising, an oxidic protective layer is created on the surfaces by anodic oxidation, which effectively protects the surfaces from corrosion caused by environmental influences. In contrast to substructures made of wood, metal substructures with our aluminium profiles do not run the risk of the material rotting over time due to moisture. Especially for facade cladding where the substructure is covered by the cladding material, the durability of rust-free metal is a significant advantage. This has a particular effect on the running costs for renovation and building maintenance.

The profiles, whose cross-section is reminiscent of the letter Z, have a total width of 78mm and a depth of 30mm. This results in a minimum distance of 30mm between the facade panels and the wall, which contributes to sufficient rear ventilation of facade cladding and also enables optional thermal insulation of the facade. The support surfaces for mounting on the wall or the facade panels are 40mm on each side, ensuring sufficient clearance for the placement of hole drillings for wall fastening or for riveting the panels. The profile thickness of 2mm not only provides excellent torsional rigidity of the Z-profiles, but also ensures a very high load-bearing capacity, so that the profiles can also be used with heavy HPL panels or fibre cement panels in higher panel thicknesses.

Approvals & Standards of the anodised Z-profile

- Manufacture from aluminium in accordance with DIN EN 755-2 and DIN EN 573-3

Mounting the aluminium Z profiles made of black anodised aluminium

Z-profiles are attached vertically to the facade in substructures of facade claddings before the facade panels are riveted or glued to the profiles. In this case, Z-profiles are usually used as the outer profile rails of the substructure, where only a single panel is attached. It is important to ensure that the support surface for mounting the facade panel is aligned with the inner side of the substructure so that holes drilled in the panel have sufficient edge clearance. In this way, edge breakouts of the panel holes can be effectively prevented.

Z-profiles are also excellently suited as intermediate profiles of the substructure for the installation of heavy or large-format cladding panels where fastening is provided within the outer edge fastenings. For intermediate profiles where two cladding panels are adjacent to each other, we also offer V-profiles at favourable graduated prices in a length of 2000mm in our online shop.

Application examples for aluminium facade profiles

- Anodised aluminium Z-profiles are ideal for long-lasting substructures without further maintenance costs

- Aluminium profiles are ideal for mounting HPL panels with our facade rivets

- With facade profiles, rear-ventilated facade claddings are very easy to erect

- Z-profiles are used as end profiles on the outer sides of substructures

- For large facade panels, Z-profiles are used as intermediate profiles for fastening

For mounting on the wall side, we recommend impact anchors or threaded bolts in size M8 with dowels to match the material of the facades. These usually have a metric thread to fasten the facade profiles with a lock nut. The number of wall fixings depends on the nature of the substrate and the weight of the facade panels, and cannot be generalised.

We recommend our ground HSS drill with a diameter of 8 mm for drilling holes in the wall fastening. For the installation of facade panels, the hole drillings of the panel should be transferred to the substructure. If facade rivets are used, always drill the substructure with a drill bit that corresponds to the rivet size. For our facade rivets, we recommend our HSS-G drill bit with 5.1mm diameter. When installing the facade panels, please always follow the installation instructions of the cladding panels to ensure sufficient fastening.

Technical data of the Z-profile made of black anodised aluminium

- Material: Aluminium AW 6063 T6

- Alloy: AlMgSi 0,7

- Surface: Anodised

- Colour: Black

- Profile strength: 2mm

- Profile depth: 30mm

- Total width: 78mm

- Mounting surface wall: 40mm

- Mounting surface plate: 40mm

- Uv-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID UK-001 Standart Length 2000 Delivery Time Dispatch within 2 - 3 working days EAN/GTIN 4260604226381 Material Aluminium anodised Profile type Z-Profile Weight 0.5750 Color Black Color accuracy No Color designation Black - Reviews