EDPM lead substitute grey - 10m roll (self-adhesive)

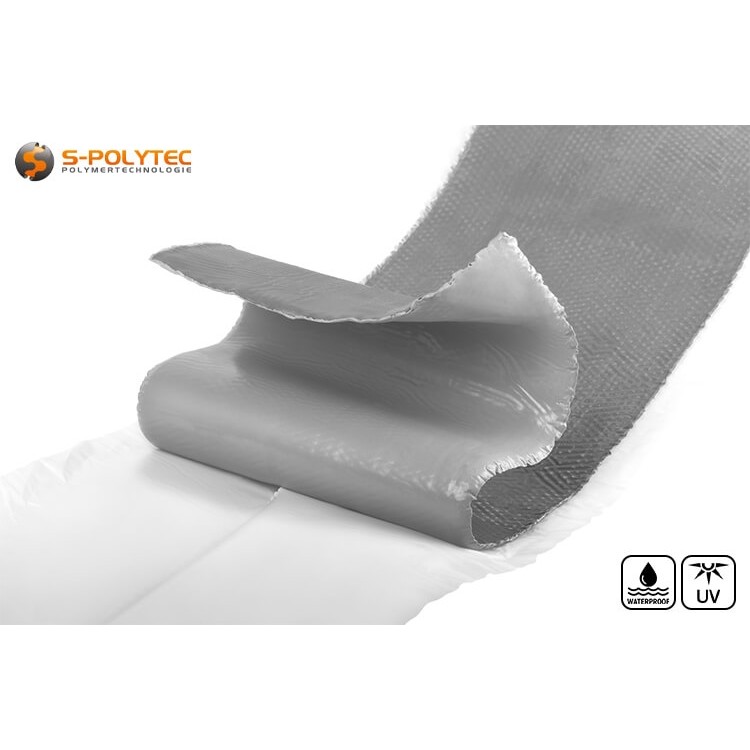

The EPDM sealing tape, which replaces lead, is grey with internal expanded metal made of stainless aluminium for consistent malleability. It is ideal for reliable waterproofing of all types of buildings, both indoors and outdoors, and is an excellent alternative to rigid rolled lead.

✓ With EPDM adhesive surface

✓ Inner layer made of aluminium fabric

✓ Very easy to shape

✓ Easy to cut to size

✓ 100% UV & weather resistant

✓ 100% Sealed - Guaranteed

The EPDM sealing tape in grey is available in rolls of 10 metres in length and either 150mm or 300mm in width.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

EPDM lead substitute in grey – 100% weatherproof. 100% watertight.

Reliable self-adhesion ✓ Internal aluminium mesh fabric ✓ 25-year warranty ✓

Our grey EPDM sealing tape, a modern replacement for lead, is available in two versions as a 10-metre roll and provides a durable, weatherproof and waterproof seal. The structure consists of three functional layers. A strongly adhesive EPDM adhesive side, a resistant, granulate-coated EPDM top layer in grey and an integrated metal mesh made of stainless aluminium. This combination makes the tape particularly light, dimensionally stable and flexible in use. The self-adhesive underside ensures reliable adhesion to almost all common building materials – from concrete and plaster to brick and plasterboard. Thanks to its high resistance to UV radiation, rain, temperature fluctuations and mechanical stress, the EPDM tape is ideal for a wide range of sealing tasks both indoors and outdoors – and provides effective protection against moisture penetration, draughts and weather influences.

The EPDM sealing tape in grey with a granulated top layer is available in roll widths of 150mm or 300mm with a roll length of 10 metres. For shorter sealing jobs, the 2mm thick tape can be easily cut with household scissors. The grey sealing tape is ideal for very grey or metallic surfaces, such as galvanised downpipes, rain gutters, profiled sheets and roof edge sheets, and ensures a virtually invisible seal.

Properties of flexible lead substitute in grey

Our EPDM lead substitute consists of three carefully coordinated layers of material. At its core is a slightly flexible expanded metal made of stainless aluminium, which ensures high dimensional stability – ideal for uneven surfaces, angled connection areas or when laying over profiled roof tiles. The underside consists of a specially coated EPDM with strong self-adhesive properties, which adheres reliably to almost all standard building materials. The top layer – a durable, granulate-coated EPDM in grey – provides lasting protection against weathering, mechanical stress and impact. This intelligent combination of materials results in a highly functional sealing tape that provides a permanent airtight and watertight seal – backed by a 25-year manufacturer's warranty on watertightness.

Thanks to its three-layer compressed construction with a total thickness of only 2mm, the sealing membrane can be installed without much effort, even in tight curves and awkward corners. Unlike rigid materials, such as rolled lead, the material adapts flexibly to a wide variety of shapes. The integrated aluminium mesh gives the sealing tape additional stability, while allowing moderate stretching. This means that even round structures, such as concrete pillars, can be sealed cleanly and completely – without having to cut or adjust the EPDM material.

Advantages of lead replacement made from EPDM

- The grey EPDM sealing tape adheres very reliably to all standard building materials

- Waterproof and airtight sealing thanks to full-surface bonding with the substrate

- Very easy to use and cut with simple scissors thanks to self-adhesive backing

- The internal aluminium fabric makes the lead substitute easy to shape

- The sealing tape can be used to repair leaky gutters and downpipes

- Self-adhesive, ideal for quickly sealing leaks in membranes and tiles

NOTE: For optimum adhesion of the grey EPDM sealing tape, the processing temperature must be above +5°C.

Application and handling of self-adhesive EPDM lead substitute

The grey EPDM lead substitute is a reliable solution for sealing work on buildings – both indoors and outdoors. It is particularly useful when installing skylights or weatherboards to effectively prevent moisture, rainwater or standing water from entering. In addition, the material is ideal for transitions from flat roofs, garages or chimneys to vertical wall surfaces. The tape also provides lasting protection when connecting window frames, door frames or canopies to existing masonry. It can also be used as a repair aid for leaks in roofing membranes or cracked roof surfaces – even downpipes and gutters can be sealed with it in a colour that is inconspicuous but reliable.

Before applying the sealing tape, ensure that the substrate is stable, clean and dry. Dust, oil or other residues impair adhesion and must therefore be thoroughly removed. The material is then cut to the required length – it is advisable to allow at least 10cm overlap on each side to ensure a secure seal to adjacent tiles or masonry. In the case of corrugated or profiled roof tiles, the length should also be slightly more generous, as the structure results in a larger effective laying area.

To install the sealing tape, first remove the protective film from the adhesive backing. Then apply the adhesive side to the desired starting point on the component. Ensure that there is sufficient overlap of at least 100mm. The visible side with the matt grey, granulate-like surface should always face outwards. The tape is now aligned along the desired route and pressed down step by step. Hold the rear end slightly raised off the surface while applying the material with the other hand, following the shape of the surface. Once the desired length has been applied, the EPDM tape can be easily cut with a pair of heavy-duty scissors. Finally, the seal is fixed evenly to the surface of the substrate by applying pressure. Particular care must be taken in corners or recesses to ensure that the tape is bonded over the entire surface without any gaps.

TIP: For longer distances, we recommend removing the backing film piece by piece so that the adhesive surface does not accidentally come into contact with the substrate and stick to the wrong place.

For very long sections where the total length to be sealed is greater than the roll length, or if you have measured incorrectly and the cut sealing tape is slightly too short, you can add another piece. However, this should overlap by approx. 10cm so that there is no gap at the transition and absolute tightness is ensured. An overlap of the sealing tape may also be necessary for sharp external corners, such as the outer chimney wall. Either seal all sides separately and then seal the corners separately with sufficient overlap so that no moisture can penetrate at the joints, or seal the masonry all around in one piece and cut the lower unwound area with scissors. Here, too, the corner area must later be covered with another piece of grey adhesive sealing tape with sufficient overlap.

Technical data for self-adhesive EPDM sealing tape

- Product type: EPDM sealing tape

- Material (outer): EPDM-rubber

- Material (inner): Aluminium expanded metal

- Colour: Grey

- Roll length: 10m

- Roll width: 150mm resp. 300mm

- Version: Self-adhesive

- Material strength: 2mm

- Water resistance: W1 (waterproof)

- Temperature resistance: -40 °C - +120 °C

- UV-resistance: Excellent

- OZONE-resistance: Excellent

- Weather resistance: Excellent

- Chemical resistance: Excellent

- Warranty: 25 years waterproof guarantee

Cleaning and maintenance of building waterproofing

Over time, the EPDM sealing tape can become dirty due to leaves, dust and dirt particles in the environment. This is not a problem and is merely a visual issue that can be easily remedied with a sponge and some soapy water, if desired and if the areas are easily accessible. Cleaning masonry, roofs or floors with a high-pressure cleaner also has no effect on the watertightness of the building seal, but you should avoid directing the water jet directly at the adhesive edges or working from too close a distance. Highly concentrated cleaning agents should also not be used, or at least their compatibility should be tested on a small piece of scrap material beforehand.

- Additional Information

Additional Information

Product-ID IX-0-GR Delivery Time Dispatch within 2-3 working days Property Completely waterproof ✓ UV & OZONE resistant ✓ Version Self-adhesive ✓ Standart Length 10000 mm Standard width varriert Thickness 2,0 mm Plastic EPDM UV resistance UV resistant Color Grey - Reviews

- Attachments