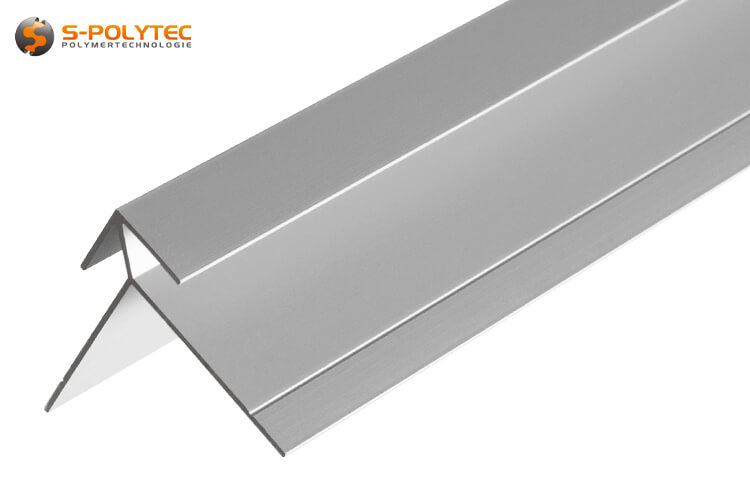

Aluminium outside corner profile silver (anodised)

Our silver-coloured aluminium corner profiles are suitable for external corners to achieve a perfect transition between slabs, wall tiles, stair treads and floor coverings and are corrosion-resistant thanks to solid production from anodised AW 6063 T6 aluminium, which means that the profiles can also be used outdoors.

✓ Solid 6063 T6 aluminium

✓ Anodised surfaces

✓ Also for outdoor use

✓ Suitable for damp rooms

✓ Very high stiffness

✓ Even surfaces

The silver anodised outer corner profiles are available in 3mm, 6mm or 8mm clamping range at favourable graduated prices.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium corner profiles in aluminium silver for outside corners

Anodised aluminium ✓ Extremely corrosion-resistant ✓ Smooth surfaces ✓

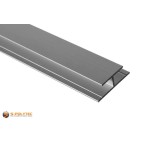

Our aluminium corner profiles for external corners are made of solid aluminium with a profile thickness of 1.1 mm and are then anodised for even better protection against the weather. The silver profiles, which we carry as a standard length of 2 metres with a clamping range of 3mm, 6mm or 8mm, are ideal for covering the edges of facade cladding, wall and floor coverings that are adjacent to each other at right angles, thereby creating a straight outer edge, even if the cutting of the panels and tiles is not perfect. In addition, the aluminium corner profiles effectively protect the corners from damage caused by impacts and prevent cuts on sharp edges of facade panels, laminate or tiles.

Due to the low profile thickness of 1 mm, the corner profiles with a length of 2000 mm can be easily cut to the required size without special tools. Moreover, the low profile thickness has the advantage that the transition from the profile to the facade panel or the floor tile is very small. On the one hand, this results in a visually homogeneous overall appearance, and on the other hand, the low transition simplifies the cleaning of panels and profile surfaces. If the profiles are used as edge profiles for stairs, the low profile thickness also has a positive effect because it does not represent a tripping hazard.

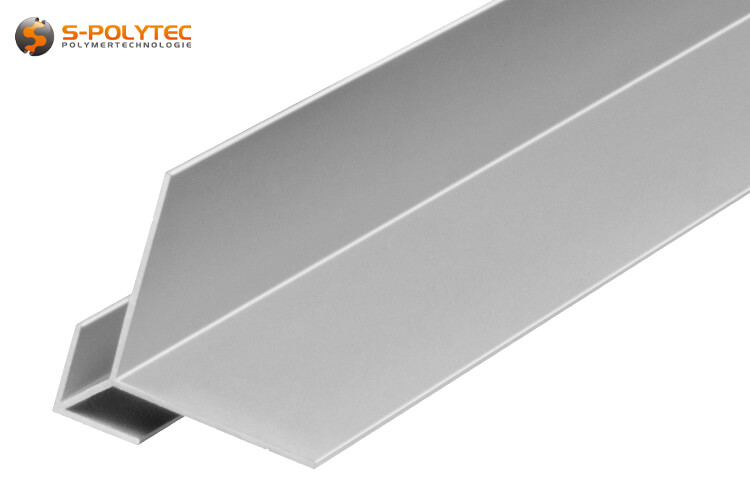

NOTE: The corner profiles in anodised finish are available in different versions for panels with 3mm, 6mm or 8mm thickness and complement the range of inside corner profiles, U-profiles and H-profiles. The length of the outer corner profiles, like all our aluminium profiles in standard length, is 2 metres.

Properties of the anodised outer corner profile

For our aluminium profiles, we rely on a robust and extremely high-quality EN AW 6063 T6 aluminium alloy, which is also colloquially referred to as architect's aluminium, especially in the construction industry. This alloy is characterised by very good corrosion resistance. The corrosion protection is further improved by the silver anodised layer, which also results in a visually uniform surface colour. The process for creating the protective layer, which takes place through anodic oxidation, is also known as anodising and contributes to the fact that the profiles are absolutely weatherproof and can be used outdoors without hesitation. This makes the silver exterior corner profiles excellent for edge covers of facade cladding, which are mounted at right angles around a house corner. In addition, robust profiles are also very suitable for indoor use, for example for covering the edges of stair treads. The very good abrasion resistance and high material quality help to ensure that the surface remains intact for a long time due to foot traffic or shoe abrasion.

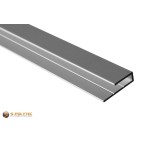

Our outside corner profiles, like all our aluminium profiles, are available as a standard length. This is always 2005mm, regardless of the clamping range. The high-quality profiles are made of solid aluminium in an AW 6063 T6 alloy. Production is carried out in accordance with EN standard 12020 (extruded precision profiles made of EN AW-6060 and EN AW-6063 alloys) with very low dimensional tolerances, whereby strict quality controls ensure a consistently high quality of the profiles. The profiles, which are designed with different clamping ranges for slabs, tiles and floor coverings in different thicknesses, vary in some cases significantly in terms of dimensions, in contrast to U and H profiles. This refers to the dimensions of the overall width, as well as the mounting surface, which is deliberately somewhat higher in the case of the 3 mm profiles, and the visible width of the profile. All edges of the profiles are discreetly rounded. The radius is 0.2mm, so that the profile edges are still perceived as angular to the naked eye, but the sharpness is significantly reduced. There is therefore no risk of cuts from the edges of the profiles.

Specific data of the different profile sizes

- Alu corner profile for outside corners 3mm: Clamping range: max. 3.5mm, visible width: 14.5mm, profile depth inside: 44.0mm, weight: 329g/m

- Alu corner profile for outside corners 6mm: Clamping range: max. 6.5mm, visible width: 15.0mm, profile depth inside: 43.5mm, weight: 321g/m

- Alu corner profile for outside corners 8mm: Clamping range: max. 8.5mm, visible width: 17.0mm, profile depth inside: 46.0mm, weight: 345g/m

Application and assembly of the aluminium corner profiles in anthracite

The corner profiles, which are mainly used to cover the edges of cladding with HPL or aluminium composite panels, are extremely corrosion-resistant and withstand all weather conditions. The silver anodised profiles not only serve to visually embellish a facade cladding in order to cover cut edges of different colours so that the black PE core of aluminium composite panels or the dark core consisting of countless layers of brown kraft paper is not visible, but also contribute to optimising thermal insulation values. By covering the necessary expansion gaps between every two panels, cold draughts can no longer get behind the facade panels so easily. Similarly, moisture caused by rain can penetrate the insulation material behind, which can rapidly reduce the insulation values. This increases the energy efficiency and thus the value of the property, and at the same time reduces the cost factor for maintenance and repair of an insulated facade cladding.

TIP: The outer corner profiles in silver anodised are manufactured in 2 metre lengths and are currently only available in standard lengths. In order to shorten them to the required length, we recommend a mitre saw with mitre function, as this offers a precise cutting result. However, a simple hand saw, for example a hacksaw, is also sufficient for sawing the 1 mm thin profiles.

For most applications, it is quite sufficient to slide the panels into the profile with a corresponding clamping area. For free-standing constructions, for example partition walls in offices or sanitary facilities, additional bonding with an MS polymer or additional screwing is recommended. A fine indentation within the mounting surface serves as a perfect guide groove for the application of the mounting adhesive and also improves adhesion on very smooth board surfaces. Floating laminate, on the other hand, should not be glued additionally so that the floor covering's ability to expand remains guaranteed. In the case of wall and floor tiles, the tile adhesive can simply be applied over the edge of the installation surface so that the tiles receive a full-surface bond.

Application examples of our profiles for outside corners made of aluminium

- The silver aluminium corner profiles are perfectly suitable as edge trim profiles for stair treads.

- The external corner profiles can be used as corner protection of tiled walls in the bathroom or food industry

- The generously dimensioned visible profile width covers and thus straightens unclean cut edges

- The wide mounting surface provides optimum stability for free-standing constructions and partition walls

- Aluminium corner profiles Significantly reduce the risk of cuts on cut edges of slabs and tiles

Technical data of the aluminium corner profiles

- Material: Aluminium anodised

- Alloy: EN AW 6063 T6

- Surface: Silver anodised

- Colour: Aluminium silver

- Profile shape: Corner profile (outer corner profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength: 1,1mm

- Visibility: 14,5mm - 17,0mm

- Profile width: 43,5mm - 46,0mm

- Mounting surface: 35,0mm - 38,0mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID AL-AEP-000P000 Standart Length 2000 Delivery Time Dispatch within 2 - 3 working days Material Aluminium (EN AW 6063 T6) Profile type Outside corner profile Version varies Color Metallic Color accuracy No information available Color designation Silver anodized - Reviews