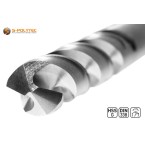

Ø 28mm HSS bi-metal hole saw

Our 28 mm bi-metal hole saw impresses with its enormous stability, thanks to the combination of HSS steel and cobalt-alloyed M42 steel. The progressive alternating toothing guarantees precise, clean holes in aluminium, wood, HPL, plastic and light metals.

✓ Made of cobalt-alloyed bimetal

✓ Enormous durability & sharpness

✓ Progressive alternating gearing

✓ Centre drill replaceable

✓ Incl. steel ejector spring

The 28 mm hole saw is ideal for our optional LED lighting for our aluminium patio covers.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€7.90 / pc.

0,0900 kg / pc.

All prices include 19% VAT.

- Description

Ø 28mm hole saw for aluminium, wood, plastic & light metal

Alloyed bimetal ✓ Progressive Vario toothing ✓ 34 mm cutting depth ✓

Our bi-metal hole saw with a diameter of 28 mm is ideal for drilling holes for the LED lighting in our aluminium patio covers. With a cutting depth of 34mm, it is a universal tool for creating precise cut-outs in a wide variety of materials. The hole saw is made from HSS steel and cobalt-alloyed M42 steel. This combination impresses with its precise cutting performance and long service life. A solid triangular shank is used as the holder, which can be used in all cordless screwdrivers and drills with a drill chuck and, unlike the cylindrical shank, always ensures a firm, secure fit when drilling. In contrast to our other hole saws with Ø60mm or Ø68mm, this is firmly connected to the crown and has an easily accessible grub lock to make it easy to replace the centre drill bit made of profile-ground HSS steel if necessary. The robust steel spring is used for easy ejection of the drill core, but can also be easily removed if this is not required to achieve greater cutting depths.

Compact and versatile - the 28 mm bi-metal hole saw from S-Polytec!

Thanks to the alternating toothing of the HSS bi-metal hole saw, precise cuts are guaranteed in the roof struts of the aluminium patio roofs to equip them with our outdoor LED spotlights, even late at night or in the dark season. The saw can also be used to feed cables, heating pipes or water pipes through drywalls made of plasterboard or OSB boards, as this professional hole saw is also suitable for drilling wood, light metal, plastic, HPL boards, chipboard or even screen printing plates.

Features of the 28 mm bi-metal hole saw

Our hole saw with a diameter of 28 mm and a maximum cutting depth of 34 mm is made from durable bi-metal. This means that two very high-quality steels are combined here to achieve a better, more precise cutting performance. The combination of HSS steel (high-speed steel) and alloyed M42 steel with a high cobalt content ensures outstanding durability and resistance. This is a significant advantage, especially for intensive use. Thanks to the progressive vario-toothing, in which the individual teeth are alternately inclined slightly inwards and slightly outwards, fast drilling progress is guaranteed in all suitable materials. These include materials such as wood, plastic, aluminium and other light metals or HPL and drywall panels. The holes in the side of the crown wall serve to quickly remove the drilling dust while also facilitating the removal of the drill core.

Thanks to the solid shank, our hole saw can be clamped in all commercially available drills and cordless screwdrivers with drill chucks. The advantage of the triangular shape of the shank holder is that it prevents the saw from spinning, because unlike a round cylindrical shank, it guarantees reliable and stable fastening in the drill chuck during operation, which is particularly useful for deep cut-outs. In contrast to our hole saws with larger diameters, which have a 5/8" x 18 UNF thread (unified national finethread) for screwing on the drill bit, the drill chuck holder on the 28 mm hole saw is permanently attached to the drill bit. However, our smaller hole saw also has a replaceable centre drill. The drill bit itself has a diameter of 6 mm and can easily be replaced with a drill bit of a different type. For drilling wood, a wood drill bit, a solid carbide drill bit for HPL panels or a special plastic drill bit of type HK for cut-outs in plastics could be inserted into the holder and fixed in place, as long as the diameter of the drill shaft is 6 mm. Suitable drill bits for replacement for a wide range of materials are available at very favourable graduated prices in our online shop.

Advantages of our hole saw with 28 mm diameter

- Manufactured from bimetal (HSS and cobalt-alloyed M42 steel) for maximum service life

- Suitable for materials such as wood, plastic, aluminium or HPL and drywall panels

- With Ø 28 mm, the hole saw is ideal for our outdoor LED spotlights for patio roofs

- The maximum cutting depth is 34 mm, but can be increased after breaking out the drill core

- The progressive alternating toothing ensures effortless cutting without tilting

- Slotted holes on the side ensure the smooth removal of drilling dust and sawdust

- The fixed shank has a grub lock for replacing the centre drill bit

- The triangular shank guarantees a tight fit in devices with a drill chuck

Application and handling of the 28 mm hole saw

We have added the S-Polytec hole saw with a diameter of 28 mm to our range especially for our LED outdoor lighting. These are very compact recessed spotlights for installation in the roof struts of our aluminium patio roofs. To install the optional lighting, however, the aluminium profiles still need to be drilled in the desired position. With a maximum cutting depth of 34 mm, however, it is much more versatile than just sawing a few cut-outs in aluminium just a few millimetres thick, as the hole saw is suitable for many different materials, including soft to medium-hard wood, wood-based panels, HPL panels, insulating panels and plasterboard. Light metals can also be easily processed with the hole saw. This is particularly useful in mechanical engineering, for example for laying hydraulic, compressed air or electrical lines in larger machines and systems. The small diameter of just 28 mm is also ideal for the construction industry. For feed-throughs for heating pipes or water pipes in drywalls or cable feed-throughs in wooden ceilings and façade panelling are just a few possible areas of application.

Precisely drilled thanks to ground centre drill bit

A hole saw is only as good as its teeth. It is not for nothing that we use alternating teeth on the bi-metal hole saw, where each successive tooth is angled slightly inwards or outwards. This widens the saw groove so that the saw has easy play and can work its way through the material with significantly less effort. This results in extremely precise and fast cuts. The hole saw is equipped with a sharp HSS drill bit to make the holes in exactly the desired position. This is profile-ground and therefore works effortlessly through metal, plastic or wood, whereby the drill bit can also be easily replaced with a wood, solid carbide or HK drill bit. The length of the drill bit has been selected so that it can be positioned at the drill hole in a clearly visible position without the red crown of the saw obstructing the view. The drill bit also ensures very precise guidance of the hole saw so that the edges of the cut-outs are evenly round and precise.EXPERT TIP: For HPL panels, simply use a 6 mm solid carbide drill bit as a centring drill for maximum precision.

Small, energy-saving & extremely durable

To reduce the effort required when drilling, two elongated holes are arranged in the crown wall of the compact hole saw, which quickly remove the drilling dust or chips and thus significantly reduce friction. For this reason, the 28 mm hole saw can also be used with less powerful cordless screwdrivers without any problems. Another advantage of the slotted holes, in combination with the alternating toothing, is the lower heat development. This results in a longer service life for the hole saw. In addition, higher speeds are also possible, which is particularly noticeable with higher thicknesses of the material to be drilled due to faster drilling progress.Work faster thanks to fast ejection

The drill core can get stuck in the drill bit, especially when cutting holes with a small diameter and greater cutting depth. To prevent this, our hole saw is equipped with an inconspicuous but effective steel spring that is simply placed over the drill bit. To achieve the maximum cutting depth, however, this spring can simply be removed again. Although the drill core is then no longer ejected forwards by the robust spring, it can still be removed very easily using a conventional screwdriver as an aid. This is used as a lever in the side holes, whereby the cut-out from the drill bit is guided forwards.Technical data of the bi-metal hole saw

- Product type: Hole saw

- Material hole saw: Bi-metal (HSS steel, cobalt-alloyed M42 steel)

- Drill material: HSS

- Ø Hole saw: 28mm

- Ø Drill: 6,0mm

- Drill length: Round

- Interlocking: Coarse, alternating toothing

- Tooth spacing: approx. 7mm

- Cutting depth: 34mm

- Direction of rotation: Clockwise rotation

- Mounting thread: 5/8" x 18 UNF

- Mounting shaft: Ø 9mm (triangular shank)

- Drill holder: Ø 6mm (round shank)

- Ejector: Yes, removable steel spring

- Suitable materials: Aluminium, HPL, wood, light metal, plastic, plasterboard

- Additional Information

Additional Information

Product-ID LS-BM-28 Delivery Time Dispatch within 2-3 working days EAN/GTIN 4260604222802 Material Bi-metal (HSS steel, cobalt-alloyed M42 steel) Property Ø 28 mm (progressive alternating teeth) Weight 0.0900 - Reviews

- Attachments