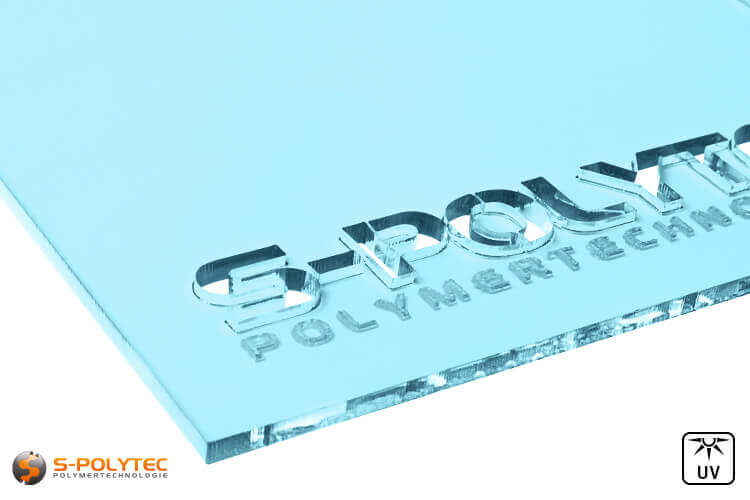

Acrylic glass light blue laser-cut

Configure individual laser parts made of weatherproof acrylic glass in light blue at a reasonable price. Available in 3mm thickness up to 1500mm length and 980mm width. The sheets are transparent and have a slightly reduced light transmission of approx. 64% due to the light blue tint.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Configure acrylic glass light blue in laser cut online

Our light blue acrylic sheets are easily, inexpensively and individually configurable online as laser parts up to a maximum size of 1500mmx980mm. The transparent sheets with light blue tint are very translucent. However, due to the colour pigments, the light transmission is slightly reduced to about 64%. For laser-cut acrylic glass in light blue, we only use cast acrylic glass sheets of the best possible quality. Due to the special manufacturing process, cast sheets are much more suitable for laser cutting, which has a particular effect on the quality of the cut edge. Due to the laser cutting process, the cut edges are smooth and polished and almost approach the look of the high-quality, glossy surface in terms of evenness and gloss level.

The acrylic glass sheets are completely dyed. This means that the surfaces and cut edges have the same blue colour. In addition, our sheets are always solid acrylic glass made of solid core material. We do not process any hollow chamber or double web sheets on our CO2 laser systems.

NOTE: Our transparent acrylic sheets in light blue have an easily removable protective film on both sides and serve to protect the surface. However, this must be removed before thermoforming, as the protective films are not thermoformable.

Properties of the transparent acrylic glass in light blue

Light blue acrylic glass is created by adding transparent colour pigments during the manufacturing process of conventional acrylic glass. The colour pigments do not affect the properties of the plastic, so that the coloured sheets also have very good UV and weather resistance. Especially with coloured plastic sheets, the ultraviolet radiation of sunlight can cause the colours to fade and the plastic to become brittle. Due to the natural UV resistance of acrylic glass, this is not to be feared with the light blue sheets, so that the laser cuts can be used outdoors without any problems. With a temperature range of -40°C to +80°C, PMMA defies both deep frost and summer heat without any problems. PMMA is the abbreviation for the chemical name polymethyl methacrylate and is mainly used in the plastics industry. For those outside the industry, especially in the private sector, acrylic glass is usually referred to as Plexiglas®. However, Plexiglas® is merely a registered brand name of the company Röhm GmbH for acrylic glass.

Compared to other transparent plastics, acrylic glass has a very hard surface. This has the advantage that the surfaces are relatively insensitive to scratches. However, PMMA is also relatively brittle, which means that the sheets can break more quickly in the event of impacts or blows. Compared to conventional glass of identical size and thickness, the impact resistance of the plastic is still 8-10 times higher, but it weighs only about half as much, which is why acrylic sheets are not infrequently used as glass substitutes.

Due to the light blue tint of our acrylic sheets in light blue, the light transmission is reduced to about 64%. For this reason, and not least because of the colour distortion of the incident light, blue PMMA is found rather rarely as plastic glazing. However, for colourful advertising stands, for example for new products, or for print media, laser-cut acrylic glass in light blue is very suitable. For engraved doorbell plates, lampshades and lighting elements, this colour is also very popular due to its subtle tint. Light blue acrylic glass is also ideal for coloured shelves in display cabinets and cupboards, optionally with lighting, or as advertising lettering in the form of individual letters.

- Acrylic glass in light blue is weatherproof, UV and weather-resistant and suitable for indoor and outdoor applications

- Light blue acrylic glass is comparatively insensitive to scratches due to its high surface hardness

- Light blue acrylic glass has 8 to 10 times the impact strength of real glass in the same format

- Light blue acrylic glass can be used permanently at temperatures between -40°C to +80°C

- Light blue acrylic glass has a fairly high light transmission of approx. 64% despite the blue colouring

- Light blue acrylic glass has a uniform and continuous pigmentation in a delicate light blue

- Light blue acrylic glass is classified as normally combustible according to DIN 4102 B2 and UL94 HB

Advantages of clear acrylic in light blue laser cut

With our laser part configurator, you can very easily configure your individual laser parts from the most common basic shapes. You can choose from circles, rings, ellipses, triangles, rectangles, routes, polygons and many more, which can be further customised in different ways depending on the basic shape. Even hole drillings can be placed with little effort, for example to be able to mount the laser cuts on a wall later. All inputs affect the shape, the weight and ultimately the price of the laser part. For this reason, both the true-to-scale preview and the price calculation are displayed to you in real time at all times. Depending on the weight and quantity required, even quantity discounts are deducted in real time so that you are always shown the best possible low price.

As soon as we receive your order, the rest is done very quickly and almost completely automatically. The configuration is sent directly to our laser system as a finished file and only the placement of the light blue plates has to be done by hand. This not only enables us to achieve very short delivery times, but also eliminates set-up costs, which primarily has an effect on the very favourable price for our laser cuts via the online configurator.

- Light blue acrylic laser parts are very easy to configure with our online configurator

- Lower tolerances are possible with laser cutting than with conventional saw cutting

- With laser cutting, the cut edge is not cloudy and saw-rough, but translucent and shiny

- With our laser part configurator, almost all shapes are possible than with our panel saws

- Thanks to automated production processing, short delivery times and favourable prices are guaranteed

NOTE: For our light blue acrylic in laser cut, the maximum size is 1500mmx980mm.

Post-processing of the acrylic laser cuts in light blue

Our laser cuts are manufactured exactly according to your desired configuration, so that further cutting of the blue acrylic sheets should not be necessary. In principle, however, the coloured acrylic glass can be cut to size very easily. Simple tools that are also used for woodworking are sufficient for this. For chip-removing operations such as sawing, milling or drilling, a medium speed and a medium feed rate should always be selected for plastics. For sawing, we also recommend a saw blade with medium-density teeth for the smoothest possible cutting edge without chipping or splintering. For drilling, an HSS drill bit for metals is most suitable. When working on the acrylic sheets, always make sure that they rest on a firm, level surface. This helps to avoid chipping or breaking the sheet.

TIP: On request, we also manufacture more complex laser parts according to your drawing from the transparent acrylic sheets in light blue with high precision at favourable prices.

Sometimes a flat sheet of acrylic is not sufficient and that is why PMMA is also very often deep-drawn into a predefined shape. However, acrylic glass must be heated for deep-drawing, otherwise there is a risk of the sheets breaking. The same applies to bending or folding the light blue acrylic sheets. The ideal temperature range for thermoforming is between 150°C and 190°C, whereby the heating time depends not only on the specific temperature but also on the thickness of the acrylic sheets.

Acrylic glass is basically excellent for bonding. This also applies to our acrylic laser cuts, because we only use cast acrylic for the laser parts you configure. Due to the special manufacturing process, cast acrylic glass does not have any internal stresses, as is the case with the extrusion of acrylic glass sheets. As a result, no stresses are released during laser cutting that lead to stress cracks when in contact with alcohol or solvents. There is therefore no need to worry about stress cracks in our laser parts, so that our acrylic glass adhesive PMMAprofi is ideally suited for bonding the laser blanks.

- Light blue acrylic is very easy to work with by sawing, milling or drilling

- Light blue acrylic glass can be excellently bonded with suitable adhesives

- Light blue acrylic can be thermoformed at temperatures between 150°C and 190°C

- Light blue acrylic glass can be screwed, e.g. with stainless steel wall brackets

WARNING: Laser parts made of light blue acrylic glass should not be cleaned with alcohol to avoid stress cracks.

Letters, logos and engravings on request

Unfortunately, there are certain technical limits with our laser part configurator, but this does not mean that we are only limited to these possibilities with our lasers. We are quite capable of laser cutting almost any shape from our light blue acrylic glass sheets. From laser parts exactly according to your specifications, to letters, numbers and lettering in any font, to elaborately designed laser engravings, almost no wish remains unfulfilled with our laser systems.

- Light blue letters, numbers, lettering in any font from acrylic glass in laser cutting

- Laser cuts according to specified design drawing in vector format in highest precision

- Hole drilling, perforated plates and cut-outs exactly according to your specifications in light blue acrylic glass

- Individual laser engravings as text or graphics on the back, front or even both sides

- Laser parts from prototype to series production with high dimensional accuracy made of acrylic glass in blue

- and much more

Further possibilities of our CO2 laser system on request:

For special requirements that are not feasible with our configurator, our friendly consulting team will be happy to help you at any time. Simply give us a call or send us an e-mail with your specific ideas.

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51071L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Blue Color accuracy Color similar to RAL color system - Reviews

- Attachments