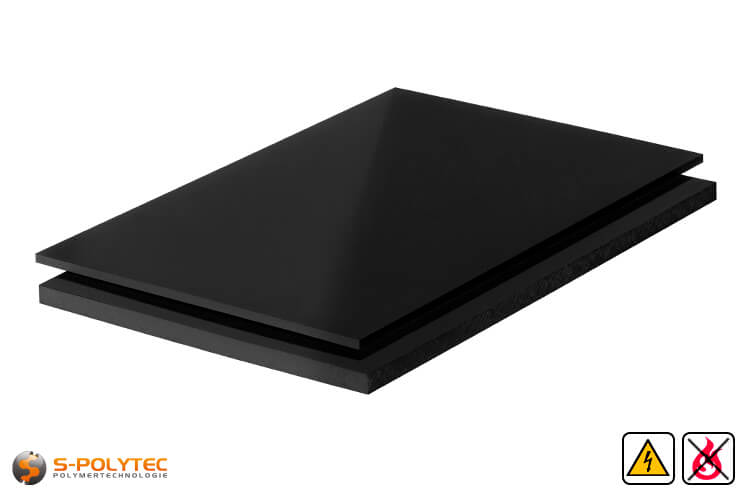

PP-EL-S sheets black 2x1meter (conductive, flame-retardant)

Electrically conductive polypropylene sheets (PP-EL-S) in black are flame retardant and available as standard sheets in the format 2.0x1.0 metres in the thicknesses: 10mm, 12mm, 15mm, 20mm, 25mm and 30mm.

✓ Electrically conductive

✓ Flame retardant

✓ Many thicknesses available

✓ Chemical resistant

✓ Made in Germany

The solid PP panels with electrical conductivity can be used in potentially explosive areas.

The item is in stock

Dispatch within 7 - 10 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PP-EL-S sheets - electrically conductive - flame retardant!

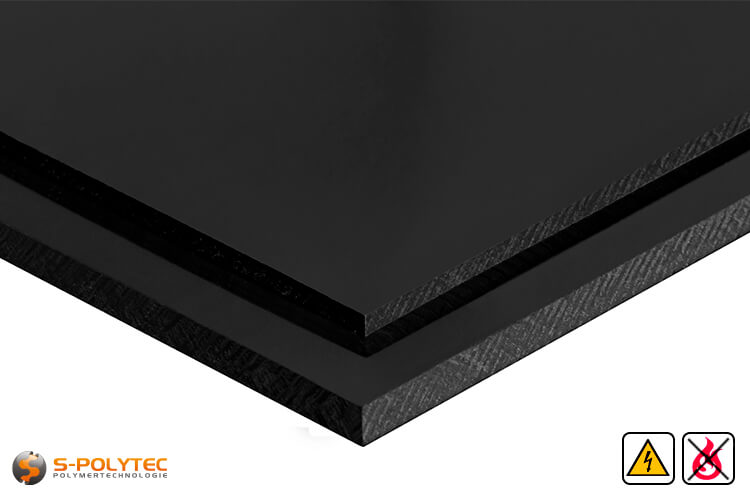

Our PP-EL-S sheets made of black polypropylene with electrical conductivity and flame retardant properties are available in our online shop in thicknesses from 10mm to 30mm. The PP sheets in standard format have a length of 2000mm and a width of 1000mm. The conductive plastic sheets are manufactured in Germany from 100% virgin material and are made from solid solid core material and do not contain a foamed core of polypropylene. The surfaces of the black panels are smooth and are supplied without protective film. To ensure a consistent colour on the surfaces and on the cut edges, the PP-EL-S sheets are completely dyed black throughout.

Note: As an engineering plastic, the black PP-EL-S with electrical conductivity is not recommended for applications for optical purposes. The surfaces of the plastic sheets are therefore also equipped without protective film.

Properties of conductive polypropylene

PP-EL-S is a permanently heat-stable and flame-retardant plastic with electrical discharge capability, which can be used to prevent electrostatic charging if it is sufficiently and permanently earthed. The static charge caused by friction, which occurs when liquid and powdery materials flow past, can lead to the ignition of flammable gases, dusts, powders, solids or liquids in the event of an uncontrolled discharge due to sparking. By dissipating the electrostatic charge, an explosion can be prevented, especially in potentially explosive areas. This is particularly true in chemical processing industries. But the electrical industry also makes use of the electrically conductive properties of black polypropylene to dissipate static charge in plant and machinery where this must be prevented.

Note: Our electrically conductive polypropylene sheets in black are not suitable as electrical conductors, but only serve the purpose of preventing uncontrolled electrostatic discharge by dissipating the electrical charge. To comply with ATEX regulations, the conductive PP-EL-S sheets must therefore be provided with a professional, sufficient and permanent earthing.

Polypropylene has a very high surface hardness (the Shore hardness of PP-EL-S is 70) and high corrosion resistance. Combined with the high chemical resistance to many acids, alkalis and solvents, the electrically conductive polypropylene is perfectly suited to all areas of application in which good chemical resistance is required, which are also subject to EU Directive RL 2014/34/EU (Directive of the European Parliament on equipment and protective systems intended for use in potentially explosive atmospheres (recast)). Therefore, the electrically conductive polypropylene is ideal for use in tank farms, refineries, paint factories, cement works, animal feed factories and many more where explosive mixtures with gases, mists, vapours or dusts are processed.

Standards for our PP-EL-S sheets in black

Our PP-EL-S has a flame-retardant additive and is therefore considered flame-retardant in accordance with the UL 94 V0 standard from a sheet thickness of 4mm and above.

The electrically conductive polypropylene sheets do not meet the approvals for food conformity according to FDA or EU 10/2011. For this reason, they cannot be used in areas of application where there is contact with food.

- REACH (EU Chemicals Regulation)

- RoHS (Regulation on the Prohibition of Hazardous Substances in the Electrical Industry)

- PAK (Directive on compliance with limit values for polyaromatic hydrocarbons)

- UL94 flame retardant V0 (from a panel thickness of 4mm and higher)

Other thicknesses or sizes of sheets made of electrically conductive PP-EL-S are available on request.

The black plastic sheets made of PP-EL-S with electrically conductive properties are available in our online shop in a standard format of 2000mm x 1000. However, if you need larger sheets, the conductive, flame-retardant polypropylene sheets in black are also available in larger formats of 3000mm x 1500mm, or 4120mm x 2010mm. Other thicknesses up to a maximum of 80mm (except 3000mm x 1000mm with a maximum thickness of 12mm) are also available on request. Simply email us with the thicknesses, sheet sizes and quantity you require and our friendly sales staff will contact you promptly with a competitive quotation.

Application examples for our PP-EL-S sheets in black

- The electrically conductive PP-EL-S is used for containers of explosive substances

- In transport and conveyor technology, PP-EL-S is used to prevent static charging

- The flame-retardant, conductive PP-EL-S is used for components in apparatus engineering and special machine construction

- PP-EL-S is used in filling systems for highly flammable, powdery materials

- and many more

Processing of our PP-EL-S sheets in black

In order to cut the black polypropylene, which we offer as sheets in the standard format of 2.0 x 1.0 metres, to the desired size, a wide variety of methods are available. PP-EL-S can be easily sawn, milled or punched. Cutting to size with a CO2 laser or a water jet cutting system is also possible with the electrically conductive PP. Drilling or turning PP-EL-S are also processing techniques that can be carried out. For simple connections of plastic parts made of black PP-EL-S with each other or with other materials, this plastic can also be easily riveted or screwed.

The electrically conductive polypropylene is excellently suited for thermoforming and so the production of finished plastic parts by thermoforming, as well as production by thermoforming, is widespread in the industrial processing of PP-EL-S. Cold forming is also frequently used, for example to produce corner profiles or bends from the black PP-EL-S sheets.

Polypropylene cannot be bonded with solvent-based plastic adhesives due to its high resistance to chemicals. With the special PP adhesive PPprofi from our own brand S-Polybond, however, we offer you an adhesive in our online shop that has been specially developed for difficult-to-bond plastics such as polypropylene. Please note, however, that this two-component adhesive is not electrically conductive.

Polypropylene can be welded very well with a suitable welding rod. This joining method is the only way to make permanent and secure connections of PP-EL-S with PP-EL-S, because bonding is not possible with conventional adhesives due to the typical properties of polypropylene, such as its very good chemical resistance to solvents. We can supply you with a suitable welding rod with electrically conductive properties made of black PP-EL-S on request.

NOTE: Our conductive PP-EL-S recycled sheets are an engineering plastic that is only suitable for optical purposes to a limited extent and are supplied without a protective film.

- Additional Information

Additional Information

Product-ID 67020S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 7 - 10 working days Plastic Polypropylene Material PP-EL-S UV resistance not UV resistant Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Jet black - Reviews

- Attachments