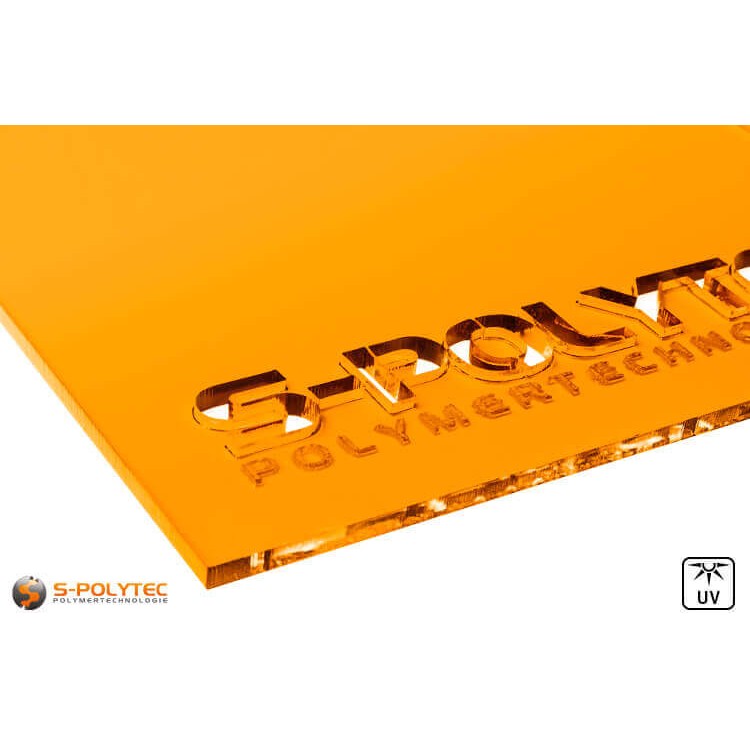

Acrylic glass orange laser-cut

Configure individual laser parts from weatherproof acrylic glass in orange at a reasonable price. Available in 3mm thickness up to 1500mm length and 980mm width. The sheets are transparent and have a reduced light transmission of approx. 38% due to the orange colouring.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Configure acrylic glass orange in laser cut online

You can conveniently buy our acrylic glass sheets in orange online in individual laser cuts at favourable prices. With our specially developed laser part configurator, almost any shape can be configured up to a maximum format of 1500mmx980mm. The plastic sheets with intensive orange colouring are transparent and translucent. However, due to the high pigmentation, the light transmission is significantly reduced to 38%. Laser cutting not only offers lower tolerances than is possible with our sheet sawing, but is also reflected in the quality of the cut edges. Due to laser cutting, these are even, smooth and polished instead of saw-rough. This ensures a comparable transparency as well as a similar gloss level as on the surfaces of the orange acrylic sheets. The excellent quality of the cut edges is further improved by the use of cast acrylic glass.

The plastic sheets made of high-quality acrylic glass are completely dyed orange to ensure that the surfaces and laser edges have the same intensive colour. The acrylic sheets we offer for laser cutting are always solid sheets and not hollow chamber sheets or double web sheets.

NOTE: Our transparent acrylic sheets in the colour orange are provided on both sides with an easily removable protective film, which, however, is not thermoformable and only serves to protect the surfaces.

Properties of acrylic glass in orange transparent

As an optical plastic, acrylic glass is a very frequently used plastic whose chemical name is polymethyl methacrylate. This plastic is also frequently abbreviated to PMMA in the trade. In common usage, however, the brand name Plexiglas® registered by Röhm GmbH is usually used as a synonym for the popular plastic. Acrylic glass is a transparent, highly translucent plastic that is available in almost all colours and designs through the addition of pigments. It has weatherproof properties, such as very good UV and weather resistance, and is therefore not only used indoors, but also very often as a glass substitute outdoors. The temperature range of acrylic glass is -40°C to +80°C and is therefore resistant to frost as well as relatively high temperatures.

PMMA is a brittle material with a very high surface hardness and therefore does not scratch as quickly as most other plastics. Acrylic glass is not as impact resistant as polycarbonate, for example, but still has 8 to 10 times the impact strength of conventional glass in a comparable format, yet weighs just half as much.

Our acrylic glass sheets in orange are certainly used less frequently as glass substitutes, but you do not have to do without the weatherproof properties of our coloured acrylic glass, because the basic properties are identical. Only the light transmission is reduced to approx. 38% by the addition of the orange colour pigments. This also affects the transparency of the sheets, which are still transparent, but not as highly transparent as clear, colourless PMMA. The transparent sheets in orange are used in a wide variety of applications. First and foremost, as with most coloured acrylic sheets, orange is probably used in advertising technology for lighting, lettering or exhibition stands. But also in the production of decorations, colourful upgrading of interiors or design objects and many more.

- Acrylic glass in orange is weatherproof, UV and weather-resistant and can be used indoors and outdoors

- Orange acrylic glass has a high surface hardness and is therefore relatively insensitive to scratches

- Orange acrylic glass has 8 to 10 times the impact strength of normal real glass

- Orange acrylic glass can be used at temperatures from -40°C to +80°C and is therefore frost resistant

- Orange acrylic glass has a reduced light transmission of approx. 38% due to the strong pigmentation

- Orange acrylic glass has a bright orange colour with uniform colouring throughout

- Orange acrylic glass is considered normally combustible according to DIN 4102 B2 and UL94 HB

Advantages of transparent acrylic glass in orange laser-cut

With our configurator for laser cuts, you benefit from simple creation for individual laser parts, entirely according to your needs and from very high precision thanks to non-contact cutting. The most common basic shapes are available for configuration, which can be further customised with additional, optional specifications. Circles, rings, ellipses, stars, triangles, squares or polygons can be created with just a few mouse clicks. Thanks to the true-to-scale preview, which reacts in real time to all your entries, you can always check your changes and correct them if necessary. Even when adding hole drillings, for example for fastenings with stainless steel spacers, you can check the position at any time using the preview.

Once your configuration is complete and you have finished the ordering process, your laser cut is sent directly to the laser systems in a file format that can be read by our lasers and processed there. Due to largely automated processing, not only very fast order processing is possible, but also the very favourable price, which is calculated for you in real time. The calculation reacts immediately to every change and always determines the most favourable possible price. Quantity discounts, depending on the size and weight of your configuration, are already deducted fully automatically.

- Acrylic laser parts in the colour orange are very easy to create via the online configurator

- Laser cutting ensures lower tolerances than is possible with conventional saw cutting

- The cut edge is not saw-rough and cloudy due to CO2 laser cutting, but uniform and shiny

- Almost all shapes can be configured with the laser part configurator in addition to rectangular cuts

- Thanks to fully automated processes, short delivery times and very favourable prices are possible

NOTE: The size of our orange acrylic laser cuts is limited to a maximum format of 1500mmx980mm.

Post-processing of the acrylic laser cuts in orange

With a little manual skill and simple tools, our orange acrylic glass can be processed very well. All tools that are used for working with wood are suitable for this purpose. Further cutting of our laser parts should not actually be necessary, but in case you want to make further holes or cut-outs, you should place the sheet on a firm, level surface and prevent it from fluttering. This will prevent chipping or, in the worst case, breakage of the entire panel. For sawing, we recommend a saw blade with medium-density teeth. Also choose a medium setting for the feed and the speed to prevent the chip from melting into the cut edge. For drilling holes, a sharp drill bit for metal is most suitable. Here, too, the speed should be in the medium range and care should be taken to ensure a firm base in order to avoid chipping at the edges of the hole.

TIP: On request, we can also produce laser cuts from our orange acrylic sheets according to your drawing. Of course, inexpensively and quickly.

Acrylic glass is a thermoplastic and as such thermoforming is a common method to bring this plastic into any shape, which remains after cooling. Thermoforming requires temperatures between 150°C and 190°C, whereby the heating time depends not only on the specific temperature but also on the thickness of the acrylic sheet. Bending or folding acrylic glass is also possible by heating the sheets. Without sufficient heating, acrylic glass should not be deformed or bent. Due to the brittleness of PMMA, the sheets may break. If you want to deep-draw our acrylic glass sheets in orange, the protective film on both sides must be removed first, as this is not suitable for deep-drawing.

Unlike polyethylene, acrylic glass can be bonded very well and can, for example, be excellently bonded in cold welding with our acrylic glass adhesive PMMAprofi from our own brand S-Polybond. Our laser cuts of orange acrylic glass are no exception, but only because we only use cast acrylic glass here, which, unlike extruded acrylic glass sheets, has no internal stresses. Stress cracks at the laser edges, which often occur with laser parts made of extruded material in contact with solvents, are not to be feared with our cast sheets in laser cutting.

- Orange acrylic can be easily processed by milling, sawing or drilling

- Orange acrylic glass can be excellently bonded with suitable adhesives

- Orange acrylic is thermoformable at temperatures between 150°C and 190°C

- Orange acrylic glass can be screwed together, e.g. with wall brackets made of stainless steel

WARNING: Lasered acrylic glass in orange should not be cleaned with alcohol to avoid stress cracks.

Engravings and cuttings according to drawing on request

Thanks to modern CO2 laser systems, we are able to laser almost any shape you need. Thus, laser cuts according to your template as a vector drawing, individual letters and numbers, up to complete lettering in any font or even individual company logos are quite feasible. In addition, our technical possibilities also include laser engraving on the orange PMMA sheets.

- Acrylic glass in orange as individual letters, complete lettering or logos in laser cut

- Precise laser cuts exactly to your specifications according to vector drawing in individual form

- Single perforated holes, entire perforated plates or any cut-outs from our orange acrylic glass plates

- Laser engravings as inscriptions on the back (mirror-inverted) or on the front

- Laser cuts from prototype to series production in high quantities from acrylic glass in orange

- and much more

Further possibilities of our CO2 laser system on request:

Do you have any questions about our laser service? Just give us a call or send us an email with your requirements. Our friendly advisory team will be happy to help you.

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51080L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Orange Color accuracy Color similar to RAL color system - Reviews

- Attachments