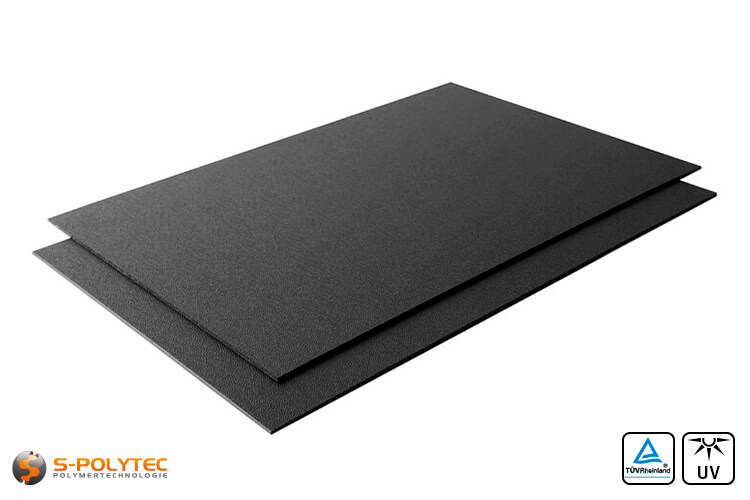

ASA/ABS sheets black grained 2x1 meter

ASA/ABS sheets in black (similar to RAL 9005, jet black) in standard format 2.0x1.0 metres in 2mm or 4mm thickness with UV-resistant ASA top layer from specialist dealer S-Polytec. TÜV-tested quality Made In Germany

The item is in stock

Dispatch within 2 - 3 working days

- Standard panels

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Black ASA/ABS standard panels in 2.0x1.0 metres

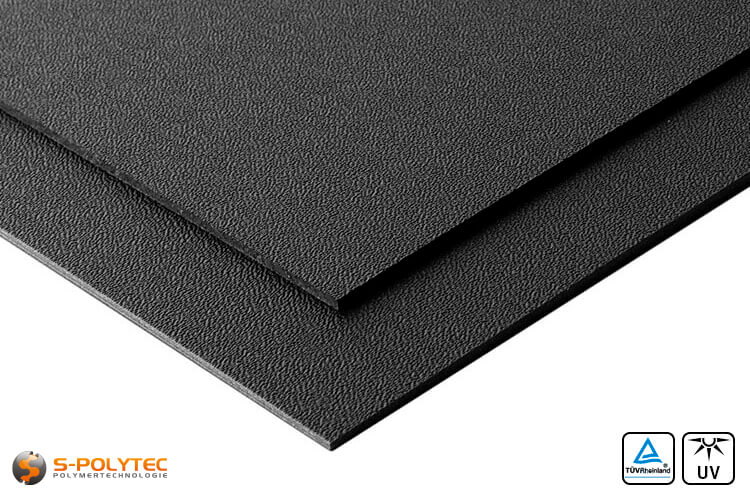

Our standard black panels made of ASA/ABS with a format of 2000mmx1000mm are available in thicknesses of 2mm or 4mm. The solid sheets are completely dyed through so that the surfaces and cut edges have the same black colour, which is very similar to RAL 9005 (jet black). The plastic panels, made of particularly impact-resistant ABS plastic as a backing material, have a special ASA top layer on one side with a medium grain (see detailed picture) that resembles the structure of leather. Due to the ASA top layer, the ABS sheets are also suitable for outdoor use. Our ASA/ABS standard panels are delivered without a protective film, but are relatively insensitive to scratching. In addition, slight scratches are barely visible due to the grained surface structure.

What is ASA/ABS?

Our ASA/ABS sheets basically consist of two different plastics that are extruded together inseparably to form a two-layer sheet. This process is also known as coextrusion. The underside of the ASA/ABS sheets consists of impact-resistant acrylonitrile-butadiene-styrene copolymer - ABS for short - and serves as a carrier sheet with a layer thickness of about 80%. The top layer, which is about 20% of the total thickness, consists of acrylonitrile-styrene-acrylate copolymer, in which the polybutadiene of the ABS is replaced by acrylic rubber in order to achieve a UV- and weather-resistant surface.

Differences between ASA/ABS and ABS

The biggest and most notable difference between ASA/ABS sheets and ABS sheets is the UV and weather resistance. Our conventional ABS sheets are not suitable for permanent outdoor use and therefore ABS cannot be used for some applications without protecting the surface from UV radiation. However, our ASA/ABS sheets are UV resistant on the ASA top layer, so outdoor use is possible without further ado. The mechanical properties of the two plastics are roughly comparable, as are the thermal properties. However, at around 92°C, ASA has a softening temperature about 10°C lower than ABS, which should not be ignored, especially for deep drawing.

Our ASA/ABS is TÜV-tested

ASA/ABS is very often used in the automotive industry, and so we have had our ASA/ABS tested by TÜV-Rheinland® for splintering behaviour, with the positive result that our ASA/ABS sheets are classified as splinter-proof. However, the test, which was carried out according to a specified procedure with several samples and test specimens at different temperatures and with different drop heights, does not apply to ASA/ABS in general, so that the test certificate is only valid for our ASA/ABS sheets in conjunction with our delivery note.

In our online shop, we also offer our TÜV-certified ASA/ABS sheets in black in millimetre-precise cuts. You can enter your required dimensions for width and length in our easy-to-use cutting configurator. You can choose between thicknesses of 2mm and 4mm for our black, one-sided UV-resistant ASA/ABS sheets. The sheets are cut exactly to your specifications on one of our modern CNC-controlled panel saws with a very low tolerance of +/-1mm.

Application examples for our black ASA/ABS sheets

- ASA/ABS sheets in black are processed into body parts in the automotive industry

- ASA/ABS sheets are used for dashboards and interior trims of vehicles

- ASA/ABS sheets are used for weatherproof covers and as privacy screens outdoors

- ASA/ABS sheets are thermoformed into impact-resistant, UV-resistant plastic mouldings

- and many more

Processing of our black ASA/ABS sheets

Our ASA/ABS standard sheets in deep black can be processed in a variety of ways. Cuts can be made by sawing or by milling. But also punching or laser cutting with a CO2 laser system, as we use for laser cutting, is possible in order to cut filigree, individual contours. ASA/ABS can also be drilled or ground.

As thermoplastics, ASA/ABS sheets can be excellently thermoformed, which is why thermoforming of ASA/ABS is used in particular in industrial series production. However, ASA/ABS is also used for thermoforming on a smaller scale, for example to produce cladding objects with individual shapes. Welding ASA/ABS in black is possible with a conventional ABS welding rod in black. No separate ASA or ASA/ABS welding rod is required for this.

ASA/ABS sheets in black can theoretically be covered with a film, but the adhesion of the film to the grained ASA surface during lamination or laminating is limited and, depending on the thickness of the film, not possible without air pockets. Painting the surfaces with a suitable paint or varnish, on the other hand, is no problem, but we recommend an adhesion promoter to ensure better adhesion of the paint.

NOTE: Due to the surface grain of the ASA top layer, our black ASA/ABS standard sheets are delivered without protective film.

- Additional Information

Additional Information

Product-ID 21120S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 2 - 3 working days Plastic Acrylnitril-Butadien-Styrol Material ASA/ABS UV resistance UV resistant on ASA surface Color Black Color accuracy Color similar to RAL color system RAL color code 9005 Color designation Jet black - Reviews

- Attachments