HPL sheets in custom cut

Our HPL sheets are available in different colours and in 6mm or 8mm thickness. HPL sheets are weatherproof compact sheets made of high-pressure laminate, whose high quality is not affected by the weather.

- HPL sheets are UV- an weather resist ans suitable for indoor and outdoor use

- HPL sheets withstand even the most adverse climatic conditions (for example deep frost or acid rain)

- HPL sheets are extremely rigid, scratch-resistant and impact-resistant

HPL sheets anthracite (RAL7016)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL panels dusty grey (RAL7037)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets light grey (RAL7035)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets silver gray

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets traffic white (RAL9016)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL panels jet black (RAL9005)

from €62.16 / m2

from €62.16 / m2Incl. 19% Tax

HPL sheets vintage look (oak white)

from €74.11 / m2

from €74.11 / m2Incl. 19% Tax

HPL sheets wood decor (dark ash)

from €74.11 / m2

from €74.11 / m2Incl. 19% Tax

VHM facade panel drill

from €39.27 / m2

from €39.27 / m2Incl. 19% Tax

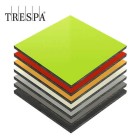

Trespa® Meteon® FR UNI COLOURS 2x1meter

from €271.50 / pcs

from €271.50 / pcsIncl. 19% Tax

Trespa® Meteon® FR NATURALS 2x1meter

from €334.15 / pcs

from €334.15 / pcsIncl. 19% Tax

Trespa® Meteon® FR WOOD DECORS 2x1meter

from €271.50 / pcs

from €271.50 / pcsIncl. 19% Tax

Buy weatherproof HPL panels cut to size online at mega low prices

Absolutely weatherproof ✓ Cut to size ✓ Fast delivery ✓

In our online shop, we offer custom-cut HPL panels in many different colours, designs and thicknesses at unbeatable prices without compromising on quality: All our HPL panels are suitable for outdoor use and are waterproof, UV-resistant and weatherproof. In addition, the robust laminate panels made of high-pressure laminate are approved for use as balcony edging and are classified as flame retardant.

What are HPL panels?

HPL panels are weatherproof, robust decorative panels that are mostly used for exterior façades or in furniture construction. They consist of different layers that are pressed together under very high pressure to form a solid panel. This is where the abbreviation HPL comes from, which stands for High-Pressure-Laminates (high-pressure laminate). The term laminated panels is also commonly used. Put simply, HPL consists of paper, wood fibres and resins and is considered particularly environmentally friendly due to its natural, renewable raw materials. During production, several layers of kraft paper made from recyclable raw materials are soaked in melamine resin and laid on top of each other. These form the usually very dark core of an HPL panel. The number of layers determines the final thickness of the panels. The outer layers consist of decorative paper, which is responsible for the surface finish. These are also soaked in resin and finally pressed together under very high pressure and heat.

HPL is available in countless colours and designs. Starting with single-colour designs in grey, black or white, through very unusual colours such as bright green or sunny yellow, to natural designs that mimic wood, stone, concrete or rust. However, all panels have one thing in common. They are unconditionally suitable for outdoor use. HPL is waterproof, resistant to UV radiation and rapid temperature changes, and even deep frost cannot damage the decorative façade panels.

Our product range for HPL panels in cut-to-size formats

- HPL panels cut to size in 6 mm and 8 mm thicknesses in anthracite

- HPL panels cut to size in 6mm and 8mm thicknesses in dust grey

- HPL panels cut to size in 6 mm and 8 mm thicknesses in light grey

- HPL panels cut to size in 6 mm and 8 mm thicknesses in silver grey

- HPL panels cut to size in 6 mm and 8 mm thicknesses in black

- HPL panels cut to size in 6 mm and 8mm thicknesses in white

- HPL panels cut to size in 6mm and 8mm thickness in dark stained ash wood decor

- HPL panels cut to size in 6 mm and 8 mm thickness in white-stained oak wood decor

Our extended product range on request

- HPL panels from Trespa® in various plain colours

- HPL panels from Trespa® in various wood finishes

- HPL panels from Trespa® in various natural finishes

- Large-format HPL cut-to-size pieces up to a maximum of 4200mmx1860mm

- HPL milled parts in desired shape according to design drawing

- and one more thing

How can I order HPL cut to size online?

In our online shop, you can conveniently order all HPL panels cut to size with millimetre precision. Select your desired panel thickness from the available options and enter the required dimensions in millimetres (not centimetres). The price is calculated immediately and automatically takes into account quantity discounts depending on the total weight of your order. Cutting is usually carried out on the next working day on one of our modern panel saws with a maximum accuracy of +/- 1 mm for the length and width of your cut-to-size panels. The use of special saw blades with a scoring function ensures flawless, perfect cut edges without breakouts or splintering.

Even more individuality with milled HPL panels

HPL cut-to-size pieces in rectangular formats can be configured and ordered via the online shop. This is the right choice for most purposes. However, our milling service offers you many more options, allowing you to mill circles, triangles or completely customised shapes from HPL. Thanks to modern CNC milling tables with three axes, we can also mill recesses, engravings or cut-outs. Our milling service can also easily drill holes for easy attachment of the HPL panels to substructures.

This is not possible using our cutting configurator, but our sales staff are available at any time to answer specific enquiries. Simply send us an email – ideally with a drawing of your milled parts – and specify the desired quantity, thickness and finish of the HPL panels. We will send you a customised quote including shipping costs as soon as possible. The quote is provided free of charge.

We process the following formats: DXF, DWG, STEP or IGES. We are also able to convert AI and EPS files.

Delivery & packaging of your HPL cut-to-size sheets

Your HPL panels will be delivered as a package or on a pallet. The decisive factors are the dimensions of the largest individual cut and the total weight of the order. Before shipping, all cuts are checked for saw edge quality and compliance with the dimensions ordered and securely packaged. Only fully recyclable material or recycled cardboard is used for packaging. Your order will usually be dispatched within 2-3 working days of receipt. Delivery with the selected shipping provider usually takes another 1-2 working days.

Note:Although HPL panels are extremely scratch-resistant, we do not err on the side of caution and cover all our HPL panels with a protective film on one side. To avoid damaging the top layer during further processing, please ensure that the panels are not pushed on top of each other or pulled over an edge.

Where are HPL panels used?

HPL plastic panels are extremely versatile thanks to their many positive properties. The laminated panels are waterproof, UV-resistant and weatherproof, and are extremely easy to clean. They are robust and easy to maintain, scratch-resistant and extremely stable.

Its high resistance to moisture, heat, UV radiation and mechanical stress makes it an extremely versatile material for countless indoor and outdoor applications. From modern façade design to privacy screens and interior fittings for heavily frequented rooms, architects deliberately choose HPL. HPL panels are also valued in furniture construction and public areas because they meet both functional and aesthetic requirements. Their wide range of colours and decors allows for individual design solutions, while their technical performance ensures long-term use.

Typical applications for HPL panels

- Facade cladding in commercial construction: Weather-resistant HPL panels for modern architecture projects

- Balcony cladding in residential construction: Durable panels for balustrades and privacy screens in outdoor areas

- Wall cladding in sanitary areas: moisture-resistant solution for shower facilities and changing rooms

- Worktops in kitchen design: hygienic, scratch-resistant surfaces for private and commercial kitchens

- Front panels in furniture construction: robust, decorative front panels for cabinets, shelves and office furniture

- Partition walls in public buildings: vandal-proof solution for schools, sports halls and train stations

- Outdoor furniture in urban design: UV-resistant HPL panels for park benches, tables and seating areas

- Interior cladding in lifts: Impact- and abrasion-resistant wall panels for lifts in apartment buildings

- Door leaves in interior design: Highly durable door surfaces in clinics, hotels or educational institutions

- Interior fittings in vehicle construction: Lightweight, hard-wearing panels for motorhomes, buses or railway carriages

Physical properties of HPL panels

HPL panels are commonly used as façade panels for exterior cladding. This is perfectly possible, as the panels are naturally UV-resistant and can withstand even adverse environmental influences such as acid rain over the long term. They absorb virtually no moisture from the environment and are therefore considered waterproof. This is also one of the reasons why these decorative panels are very often used in wet rooms such as public toilets.

The very high bending stiffness of the panels, especially our HPL panels with balcony approval in accordance with ETB guidelines, are further positive characteristics of the panels. This makes HPL suitable for use as privacy screens for balconies or fence elements or as partition walls in interior areas.

Depending on the area of application, the use of flame-retardant façade panels may be required. This is particularly the case when used on or in buildings accessible to the public. All HPL panels in our shop are classified as flame-retardant (comparable to DIN 4102 B1) in accordance with DIN EN 13501 B-s2,d0.

- Physical density:10.35 g/cm³ (depending on model)

- Operating temperatures: -30 °C up to +80 °C

- Fire behaviour:Flame retardant

- UV-resistance:Yes

- Weather resistance:Yes

- Water resistance:Yes

- Frost resistance:Yes

- Food safe:Physiologically harmless according to BfR

Note:The physical properties may vary and are therefore specified in the product description and the corresponding data sheets.

Processing of HPL panels

HPL cutting

HPL panels can be easily cut to the desired size by sawing or milling. Due to their high hardness, HPL plastics can be processed in the same way as hardwood. For sawing, we recommend a carbide saw blade with alternating teeth. A large saw blade protrusion reduces edge chipping of the decor on the underside. Depending on the panel thickness, the feed rate should be set to around 6–9 metres per minute. For our HPL cut-to-size panels, we even use two saw blades at the same time. A smaller one for pre-cutting to achieve a perfect saw edge on the underside, and another with a high protrusion for a flawless cut edge on the top. For milling individual shapes or cut-outs, carbide milling cutters have proven themselves in our company – for example, carbide spiral milling cutters for chamfering edges. It is important that the panel is firmly supported during sawing or milling.

TIP:Buy HPL panels cut to size online in our shop. We will then saw them and deliver the cut-to-size panels with perfect saw edges.

How to drill HPL correctly?

Due to its manufacturing process, HPL is very hard and therefore requires a drill bit that is suitable for this material. A conventional wood drill bit will quickly reach its limits here. However, HPL can be drilled quite well with a sharp HSS drill bit, which is normally used for metals. However, you must ensure that you are working on a firm surface and proceed with great care to avoid chipping the decorative surface at the edges of the drill hole. This is often the case when the drill emerges on the reverse side. This can be reduced by placing the panel on a smooth wooden beam so that the drill does not jerk through and instead continues to drill into the wood. With special HPL drills made of solid carbide, the risk of breakouts can be almost completely eliminated. These solid carbide drill bits have a special drill head geometry that is specially designed for hard facade panels such as HPL or fibre cement and even allow freehand drilling without a fixed base. Regardless of the drill bit, HPL should always be drilled at a moderate speed. This prevents the drill bit from overheating, which affects its service life and prevents the drill tip from annealing. The hammer drill function must also be deactivated on cordless screwdrivers or drills.

TIP:With our milling service, we can deliver your HPL panels cut to size and drilled – quickly and at a reasonable price.

How to install HPL panels?

How an HPL panel is installed depends on its size and intended use. HPL panels are often used as façade panels or balcony privacy screens and are attached to a metal or wooden substructure. When used outdoors, decorative cladding panels are subject to temperature fluctuations, which cause the panels to expand. To ensure that the panels have sufficient room to expand after installation, a non-restrictive mounting method is required for such applications. It does not matter whether they are attached to an aluminium substructure with facade rivets or to a wooden substructure with HPL screws. Even when used as balcony edging with balcony screws or rivets, care must be taken to ensure that the panel can still expand between the individual mounting points. For this purpose, it is important to have a fixed point with a hole that corresponds to the diameter of the screw or rivet. All other fastening points are deliberately drilled slightly larger. Two to three millimetres are necessary here so that the panel can expand in all directions without any problems in strong sunlight. Otherwise, HPL panels can warp due to the effect of heat. These are called sliding point fastenings.

TIP:We have posted do-it-yourself instructions for installing a balcony railing for you on our blog.

Can HPL panels be glued?

Yes, HPL can even be glued quite well. Because the panels are quite heavy compared to other plastic panels, an adhesive with high adhesive strength is required. An MS polymer – for example, Parabond 600 – has very high adhesive strength and excellent initial adhesion. It is ideal for bonding the panels to concrete, sand-lime brick, metal, wood or other building materials. MS polymers require air humidity to cure. To bond an HPL panel, apply the adhesive in waves at intervals of about 10–15 cm to ensure that air can get between the panel and the substrate. Then press the panel into the desired position. The panel should be secured against slipping or falling for about 24 hours until the MS polymer has hardened. Cyanacrylate-based instant adhesives are also suitable. However, these are recommended for smaller bondings on and from HPL panels. Solvent-based adhesives, on the other hand, are completely unsuitable because HPL is solvent-resistant and the surface cannot be dissolved for bonding.

Environmental compatibility of HPL plastics

High-pressure laminate panels are particularly environmentally friendly as they can be completely recycled and are made from renewable raw materials. Depending on the manufacturer and design, recycled paper is also used for the kraft paper during production. Offcuts and smaller sheets that are no longer required can be disposed of safely in household waste. For larger formats and higher quantities, disposal at the local recycling centre is recommended.

Since HPL is basically paper and wood fibres, it is often finely ground and used as a filler, for example for thermal insulation in the construction industry. In a waste incineration plant, discarded HPL panels can be used to generate energy. This allows some of the energy required to manufacture the multi-layer high-pressure panels to be recovered. This requires high temperatures, so we strongly advise against burning them in domestic fireplaces.