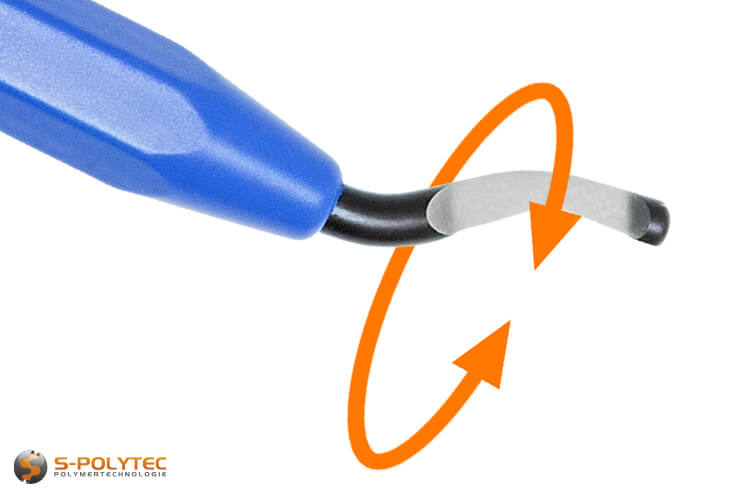

Quick deburrer with 360° blade

Our handy quick burr cutter with rotating HSS blade is perfect for edge processing and enables the effortless removal of fine burrs that occur when cutting plastic sheets.

✓ Rotating blade

✓ Blade made of durable HSS steel

✓ Easy handling

✓ Also ideal for drilling

✓ TOP Quality

Thanks to sharp 360 degree blade perfect for deburring plastics and many metals.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€7.90 / pc.

0,0230 kg / pc.

All prices include 19% VAT.

- Description

Quick deburrer for easy edge deburring

Sharp 360° blade ✓ Easy handling ✓ Ideal for plastic panels ✓

Our inexpensive quick deburrer with rotating blade is perfect for quickly deburring our plastic sheet blanks. The high-quality blade made of HSS steel is ground on both sides and glides effortlessly along the edges. Thereby, hand deburring tools are not only ideal for straight or curved edges, but can also be used for deburring holes due to the thin cutting edge. The rotating blade, which can be turned through 360°, ensures that the correct angle is always set when pulling the tool along the edge to be deburred. This makes the useful tool also suitable for inexperienced and very easy to use.

The quick deburrer, which is very similar in size and design to a biro, is equipped with a clip. This useful tool is always at hand to deburr plastic blanks directly after sawing.

As a specialist dealer for cut-to-size plastic sheets, the quick deburrer is an indispensable tool for us to carry out quick, simple edge deburring. Thanks to the sharp HSS blade, the deburrer can be used without hesitation for almost all of the plastics that we offer in our online shop. We often use this useful tool for blanks made of polyethylene, polypropylene, PVC or ABS. HPL or polycarbonate can also be processed with the deburring tool. Many plastics that are not part of our standard delivery programme and are only available on request can also be used for edge processing. These include ABS/TPU, POM, polyamide and many more. Even for metals with a low density, such as aluminium, copper or brass, as well as precious metals such as gold and silver are freed from sharp sawing edges in no time at all with the high-quality rapid deburrer.

-

Scope of delivery:

- 1 x Quick deburrer with 360° blade and clip

NOTE: The rotating HSS blade of the quick deburrer cannot be replaced.

Technical data of the rapid deburrer for plastic sheets

- Material shank: Aluminium

- Material blade: HSS steel

- Total length: 140mm

- Length blade: 20mm (10mm effective)

- Shape blade: curved

Instructions for use of the Quick Trimmer with 360° Blade

Deburring cut edges with the quick deburrer is very simple and can be done easily even by users who are less skilled in their craft. The blade is placed at the end of the edge and moved along the cut edge at a steady speed. No pressure should be applied to the tool in order to avoid jamming the blade. This is especially important for plastics with a lower density, such as polyethylene or polypropylene. With angular blanks, it is easier if the tool is placed a few centimetres away from the corner instead of trying to pull the tool over the corner edge. This will leave a small degree on the first piece, but this can be removed very quickly by reapplying the speed deburrer in the opposite direction. For very long cut edges that cannot be deburred in one movement, the tool can achieve the desired effect by reapplying and pulling off in small sections. This procedure is also the easiest way to get rid of the small degree on milled parts or saw cuts with large radii.

Deburring drilled holes requires a little skill, but is done just as quickly as with straight cuts. The blade is inserted vertically into the hole until the edge of the hole has reached about half of the curved cutting edge. The best results can be achieved if the rapid deburrer is held at a slight angle. This is followed by a light, circular hand movement. Here, too, care must be taken not to exert disproportionate pressure on the tool, because the narrower the borehole radius, the faster the sharp blade can tilt, which has a detrimental effect on the roundness of the borehole.

For cut edges with a stronger degree, or if edge breaking has not yet achieved the desired effect, this process can be repeated as often as desired until the result is satisfactory.

TIP: By repeatedly honing the edges, the curved blade can produce soft, rounded cutting edges that go far beyond normal deburring.

- The quick deburrer always sets the perfect angle of attack thanks to the rotating blade

- The sharp blade made of HSS steel is ideal for plastics, but also suitable for soft metals

- The filigree blade is perfect for easy deburring of holes, tight radii or cut-outs

- Thanks to its compact design with practical clip, the round deburrer is always at hand when needed

- The blade, ground on both sides, glides effortlessly along the edges and cleanly removes the grade

With brittle plastics such as acrylic glass, deburring with a quick deburrer is somewhat more difficult, because the hard surfaces can cause the tool to jam much more quickly than with softer plastics. With a little practice, however, the edges can be broken even in such cases. Alternatively, brittle plastics can be used with a profile scraper with a firm, straight blade, which makes it much easier to pull off the edge. With very hard HPL boards, on the other hand, the round deburrer can be used without any problems, but the very hard surface may require running along the edges several times until the grade is fully removed. In addition, with such a robust material, the blade can wear out much more quickly, which is why deburring is usually practised by edge processing with a CNC milling machine and special milling drills.

WARNING: To prevent injuries, the workpiece to be deburred should always be held at a sufficient distance from the edge.

- Additional Information

Additional Information

Product-ID SP-SEG-360F Delivery Time Dispatch within 2-3 working days EAN/GTIN 4014691259292 Material Aluminium Weight 0.0230 - Reviews