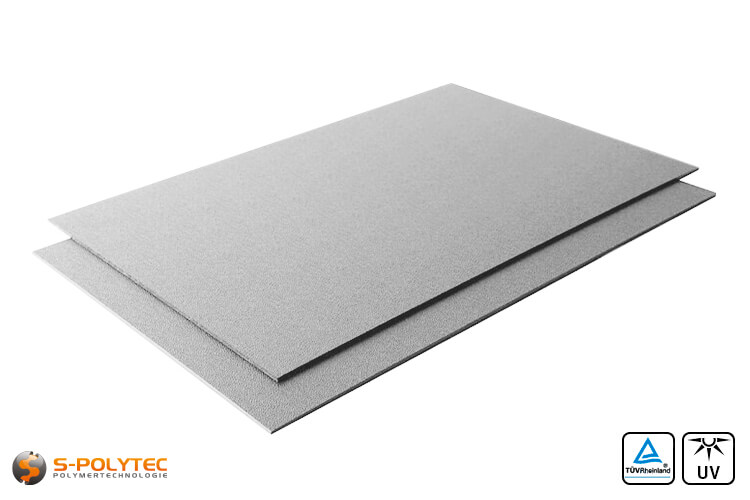

ASA/ABS sheets grey grained 2x1 meter

ASA/ABS sheets in grey (RAL 7040, window grey) in standard format 2.0x1.0 metres in 2mm or 4mm thickness with UV-resistant ASA top layer from specialist dealer S-Polytec. TÜV-tested quality Made In Germany

The item is in stock

Dispatch within 2 - 3 working days

- Standard panels

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

ASA/ABS standard panels window grey in 2.0x1.0 metres

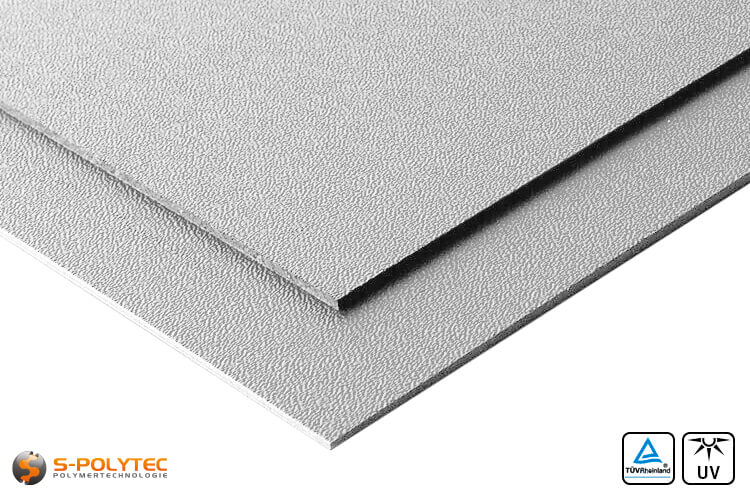

Our grey ASA/ABS sheets are available with a standard size of 2000mmx1000mm in thicknesses of 2mm or 4mm in our online shop. The panels are specially manufactured in the colour window grey according to the RAL colour system and are completely dyed through, so that surfaces and machined edges have the same colour grey, which corresponds to the colour RAL 7040 (window grey). The solid panels consist of a particularly impact-resistant layer of ABS plastic which serves as a carrier material and takes up about 80% of the total thickness. The top layer, with a thickness of about 20%, is made of weather-resistant ASA and has a medium grain (see detailed picture) that is reminiscent of the structure of leather. Due to the ASA top layer, our ASA/ABS sheets are suitable for permanent outdoor use and are therefore often used for façade cladding and roller shutter box covers or weatherboards due to the special colouring in window grey. Our ASA/ABS standard sheets are supplied without a protective film, but are relatively resistant to scratching. The grained surface structure also helps to ensure that slight scratches on the surface are hardly noticed.

What is ASA/ABS?

Our sheets made of grey ASA/ABS are fused into one sheet during extrusion in two layers of different plastics. A distinction is made between the carrier layer consisting of impact-resistant but not weather-resistant ABS (acrylonitrile-butadiene-styrene copolymer) and the top layer of UV- and weather-resistant ASA (acrylonitrile-styrene-acrylate copolymer). Through this so-called co-extrusion, the positive properties of the two plastics are combined to form a solid and inseparable plastic sheet.

Differences between ASA/ABS and ABS

ABS and ASA are very similar in terms of mechanical and thermal properties, but the temperatures for deep drawing differ by about 10%. While the softening temperature of ABS is about 102°C, this is about 92°C for ASA. This should be taken into account when thermoforming. However, the main difference and also the main reason for combining the two plastics is the impact strength of ABS and the weatherproof properties of ASA, resulting in an impact-resistant plastic sheet that can be used outdoors for years without the plastic fading or becoming brittle due to the effects of UV radiation.

Our ASA/ABS is TÜV-tested

Like our black ASA/ABS sheets, our grey sheets are classified as shatterproof by TÜV-Rheinland. With the corresponding test certificate, in which the sheets were tested for their shatter resistance, our ASA/ABS sheets can therefore also be used without further ado for the production of car body parts or interior trim in the automotive industry. The test is carried out according to defined criteria and with different test specimens at different drop heights and different ambient temperatures, in which our plastic sheets easily exceeded the requirements. Please note, however, that the TÜV certification refers exclusively to ASA/ABS sheets from our online shop (and not to ASA/ABS in general) and is only valid in conjunction with our delivery note.

In addition to the standard panels made of grey ASA/ABS in a format of 2.0x1.0 metres, we also offer our TÜV-certified ASA/ABS panels cut to size, so that you can buy the panels directly in the size you need. By specifying the dimensions for length and width in millimetres, as well as the selection from the thicknesses 2mm or 4mm, the delivery of your desired sheets is carried out in millimetre-precise cutting on one of our CNC saws with very low manufacturing tolerances of +/-1mm.

Application examples for our grey ASA/ABS sheets

- ASA/ABS sheets in window grey are used for façade cladding or window surrounds

- ASA/ABS sheets are suitable for car body parts in the automotive industry due to their TÜV certification for shatter resistance

- ASA/ABS sheets are thermoformed into UV-resistant housings for electronic equipment

- ASA/ABS sheets are impact resistant and are used in mechanical engineering for covers and housing parts

- and many more

Processing of our grey ASA/ABS sheets

Our ASA/ABS standard panels in window grey are similarly easy to process as wooden panels. The tools required are also identical to those used for processing wood. For example, ASA/ABS can be cut to the desired final format by sawing, milling, sanding or punching. Cutting with a CO2 laser can also be used for contours in any shape and is very often used by us for requests for shaped cuts from ASA/ABS.

ABS is processed by thermoforming, especially in the industrial series production of finished plastic parts such as bumpers, notebooks or housings for electrical devices. This also applies to our ASA/ABS sheets, which can be thermoformed at relatively low temperatures. The welding of ASA/ABS with each other or with ABS plastics is also frequently used in practice to achieve a permanent and secure connection of the joined parts. A conventional welding rod made of ABS is sufficient for this. No welding rod made of ASA/ABS is required. Instead of welding, our ASA/ABS can also be excellently bonded. For this purpose, we offer the special ABSprofi adhesive of our own brand S-Polybond in our online shop, which securely bonds the plastic parts in a cold welding process.

Painting of our grey ASA/ABS panels is possible with a suitable lacquer. For the best possible result, we recommend treating the surfaces to be painted with a bonding agent to ensure permanent adhesion of the paint. Basically, laminating, i.e. sticking a film on, would also be feasible, but due to the grained surface structure of the ASA top layer, it is hardly possible to apply the film without air pockets. This also results in limited adhesion of the film to the surface.

NOTE: Our ASA/ABS standard panels in window grey are delivered without protective film, as this is difficult to apply to the ASA top layer.

- Additional Information

Additional Information

Product-ID 21139S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 2 - 3 working days Plastic Acrylnitril-Butadien-Styrol Material ASA/ABS UV resistance UV resistant on ASA surface Color Grey Color accuracy Production according to RAL color system RAL color code 7040 Color designation Window grey - Reviews

- Attachments