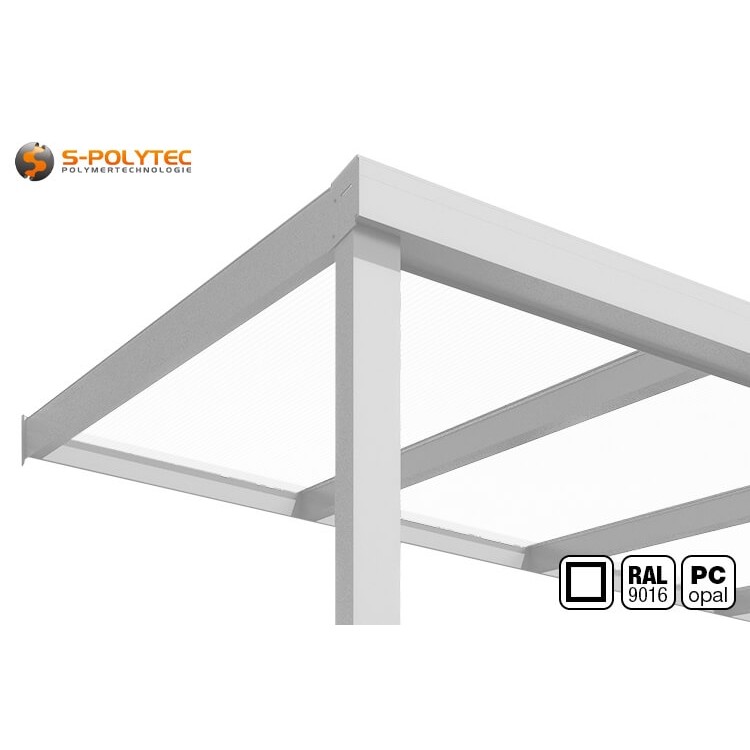

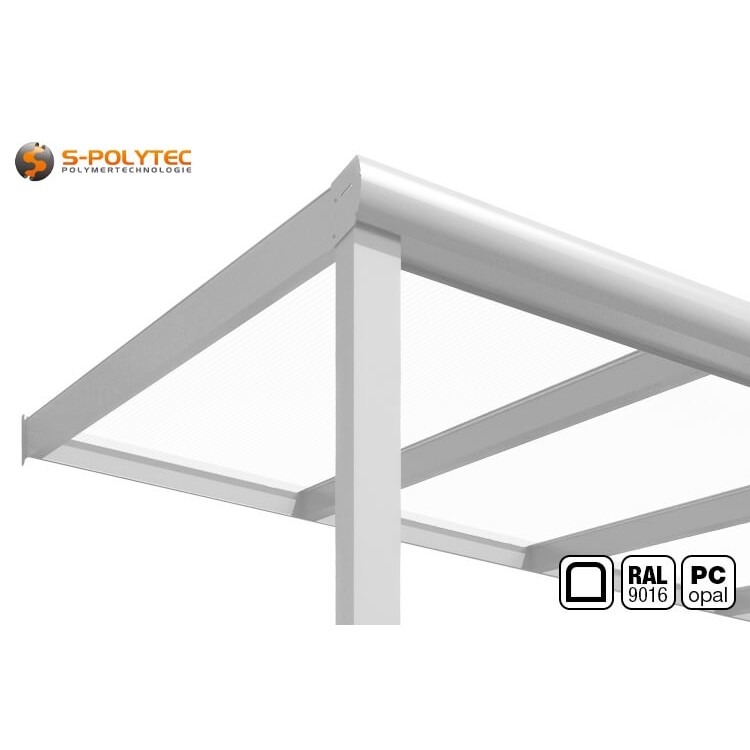

White terrace roof (polycarbonate opal)

Our terrace roofing in white with covering made of shatterproof double-skin polycarbonate sheets in opal design (frosted glass look) is available with either square or rounded profiles made of powder-coated aluminum.

✓ Two profile shapes selectable

✓ Powder coating in RAL 9016

✓ opal 16mm twin-wall sheets

✓ EN AW 6063-T6 Aluminium

✓ Snow load zone 1

The made-to-measure aluminum terrace roof can be configured in RAL9016 from 4m - 12m wide and 2m - 5m deep.

The item is in stock

Dispatch within 8 - 12 weeks

- Configure Roofing

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Patio roof in white with polycarbonate panels in opal

Double-skin panels in opal ✓ Semi-gloss powder coating ✓ Easy installation ✓

Our aluminium patio roofs with white powder coating in brilliant traffic white (RAL9016) and roof covering made of shatterproof double-skin polycarbonate sheets in opal (milky opaque) design offer protection from bad weather, strong sunlight and privacy all in one. A completely new outdoor living experience, allowing you to enjoy your patio in any weather and at any time of year. Not only do you have the option of configuring the dimensions of your roofing in terms of width and overhang, but you can also choose from two different profile shapes in angular or rounded versions. Starting from a width of 4 metres and a depth of 2 metres, up to a size of 12 metres wide or 5 metres deep, the perfect roofing can be configured for every terrace.

You are only 3 configuration steps away from your new aluminium patio roof

Your new patio roof is customised as far as possible based on your configuration. Both the opal double-skin panels and the profiles are supplied in exactly the required length for roofs up to 6 metres wide to make installation as easy as possible for you. The only exceptions are the support posts and, for roofs wider than 6 metres, the wall connection profile, the gutterprofile and the decorative front profile, which simply need to be cut to size. The hard-wearing powder coating and the use of a particularly high-quality AN EW 6063-T6 aluminium alloy not only promise unlimited enjoyment of the canopy, but also defy all weather conditions thanks to their excellent weather resistance. Above all, the increased load-bearing capacity, which is due to the superior aluminium alloy, contributes to the fact that our patio roofs with plastic roofing are all approved for regions with a snow load of zone 1. Depending on the specific combination of width and depth, they are even suitable for snow load zone 2.

NOTE: The delivery time for our patio roofing is 8-12 weeks. We think that's long too, but the real work starts from the time of configuration with the precise cutting of the double-skin polycarbonate sheets in opal and the commissioning of all components in the required quantity. Then everything is carefully packed, individually loaded by hand and delivered by a forwarding agent. Even to the terrace on request.

Features of the white patio roof with opal covering

An aluminium patio roof is the best thing you can do to yourself and your patio, because unlike wood, aluminium is maintenance-free. There is no need for annual wood protection glazing. But not all aluminium is the same. The right choice of alloy makes a difference here - both in terms of durability and in terms of stability and load-bearing capacity. We make no compromises when it comes to quality and have deliberately opted for a very high-quality EN AW 6063-T6 aluminium. Often only a simpler 6060-T6 aluminium alloy is used for canopies, which is certainly sufficient, but this is also at the expense of the discreet appearance of the profiles and the large dimensions are also not possible without further measures to improve the statics. Nevertheless, it may be necessary to integrate additional reinforcements for very large canopies with high depths. These are of course included in the scope of delivery and are simply inserted into the hollow chambers of the roof struts or the gutter. Particularly when the load caused by snowfall is taken into account, the statics play a decisive role, regardless of whether reinforcement profiles need to be used or not. Our roofs with lightweight polycarbonate sheet coverings are always approved for regions in snow load zone 1, which covers some areas in Germany as well as the whole of the Netherlands and Belgium. Some roof sizes are even approved for snow load zone 2 and can therefore be used in almost all of Germany, if you exclude high-altitude areas with the expected higher snowfall.

We rely on powder coating for the paintwork, as this creates an even, seamless layer of paint, which is characterized by an insensitive and robust surface in satin white. This coating not only protects the already robust and corrosion-resistant aluminium of the construction profiles from external influences, but also contributes to the attractive, radiant appearance of the entire roofing. UV radiation is a tricky issue, especially with light colours, because depending on the intensity, it can cause the surface to turn yellow after a short time. We counteract this yellowing with a special varnish for outdoor use, which has very good UV and weather resistance. It is not for nothing that we give a 10-year guarantee on the colour fastness of the white powder coating.

Resistance to weathering is also very important for roofing. In addition to UV resistance, which can also lead to yellowing and brittleness in opal plastic sheets if inadequate, this also includes resistance to high and low temperatures as well as strong temperature fluctuations. For this reason, we use a UV and weather-resistant type of double-skin sheet. In contrast to glass, the polycarbonate used is very light and therefore also allows us to use larger dimensions for our roofing than with toughened safety glass roofing. In addition, the lower weight also has purely visual advantages, as fewer support posts are required depending on the configuration. With around 54% light transmission, opal roofing represents the perfect middle ground between light transmission, privacy and sun protection, as the opaque design protects you from views from above as well as from strong sunlight. In addition, the roofed area and the living space behind it heats up less intensively with frosted glass-look roofing than with transparent roofing.

With a canopy, you can sit in the dry even when it rains. To ensure that the rainwater can drain away properly, our canopies have a complete drainage system that is also completely concealed within the structure for the sake of appearance. Who wants a white canopy with a perfectly formed design that is then disturbed by an ugly PVC downpipe? Even the drainage channel, which extends across the entire width, is covered by a decorative profile in a selected profile design. The drainage in the gutter takes place via a PVC pipe concealed in the support post, so that the water can be drained off at the desired position in the post via the PVC elbow supplied. To do this, a hole with a diameter of 60 mm must be drilled at the appropriate position using our bi-metal hole saw, for example.

TIP: A concrete base with integrated drainage is more attractive, as this keeps the look of the support post immaculate. Rainwater and meltwater is drained underground and can, for example, be directed into a container, collected and used for watering lawns and flowers, as well as for cleaning garden furniture, patios or the roofing itself.

Optional accessories

- Concrete base for easy installation of the support posts

- Concrete base with integrated drainage

- LED lighting in RAL9016 (dimmable, incl. remote control)

Installation of the white patio canopy with opal polycarbonate

The installation of a patio cover is subject to certain requirements and precautions. These mainly include the state of the wall and soil. The measures for installing the support posts, such as earthworks or pouring the concrete foundations, must also be carried out before the installation of the canopy can begin. Detailed information on this and illustrated step-by-step instructions can be found in the installation manual, which can be viewed, saved and printed at any time in the "Data sheets" tab.

The instructions also contain detailed information on the scope of delivery and the tools needed for assembly, which is limited to simple tools and machines with the exception of the crosscut and mitre saw. With the exception of the support posts - and for roofs over 6 metres wide, where the wall connection profile, the gutter profile and the decorative front panel consist of two or three individual profiles in standard lengths of 4060mm, 5060mm or 6060mm - none of the profiles need to be cut to size, as these are supplied in the required length, as are the opal polycarbonate sheets, which are already supplied in the correct size, so assembly can be carried out by one other person without any problems. Depending on the size, the time required is limited, meaning that the canopy can be fully assembled in one morning and used immediately afterwards without restrictions.

IMPORTANT! For roofs over 6 metres wide, the additional instructions within the installation instructions must be taken into account.

This section contains detailed information on shortening the wall connection profiles, the gutter and the decorative front profile, with exact information on how far the respective profiles must be shortened depending on the size of the terrace roof.

Assembly can be divided into 7 main steps

- 1. Fixing the wall connection profile to the brickwork

- 2. Measuring, shortening and assembling the support posts

- 3. Installing the drainage channel on the support posts

- 4. Connecting the uprights to the wall profile by mounting the side trusses

- 5. Preparation and installation of internal trusses

- 6. Preparation and installation of roofing with opal polycarbonate sheets and truss covers

- 7. Installation of internal drain

Each of these essential assembly steps consists of small sub-steps, which are clearly explained in the illustrated instructions. Some of these sub-steps are also repeated. For example, measuring and shortening the support posts is always identical and must be carried out for each individual post. Each individual rafter must also be prepared before being installed and bolted in place. These tasks include, for example, applying rubber seals, installing reinforcements (if necessary according to the configuration) or installing optional lighting. The steps that are repeated are self-explanatory, but for safety reasons are again clearly marked in the instructions with a symbol indicating the numbered work steps.

The white support posts with a standard length of 250cm must be shortened in most cases, depending on the structural conditions. This is where several factors come together that affect the dimensions. These include the installation height of the wall connection profile or the desired clearance height at the upright, uneven floors and slopes, both towards the wall and between the uprights. Shortening, however, is quite easy with a mitre saw. If necessary, a handheld circular saw with a suitable saw blade is also sufficient. To categorise the dimensions, we have created a clear table in the appendix of the instructions with installation heights and post lengths depending on the roof depth.

Required assembly tools

- Circular saw or cross-cut saw with blade for aluminium

- Impact drill

- Ø8 mm(*)Hammer drill for stone/concrete

- Cordless screwdriver

- Ø 9mm(*), 5mm and 3.5mm HSS drills for aluminium

- 13 mm spanner or reversible ratchet with socket spanner

- 5-metre tape measure

- Hole saw Ø 60mm for aluminium for drainage in gutter and support post

- Hole saw Ø 28mm for aluminium (required with optional lighting)

- Sharp knife or scissors for cutting the rubber seals

- Spade or shovel (for earthworks with underground foundations)

- Silicone gun

- Rubber hammer

- Spirit Level

NOTE: The delivery includes everything needed for complete assembly. In addition to all profiles, panels and covers, matching screws are also included. Some of these are also painted white for a visually homogeneous installation. The screws for wall-mounting the connection profile are also included, these are tapping plugs for fixing into solid stone or concrete. If the mounting surface is different, the plugs must be replaced with the appropriate fastening material. In this case, the hammer drill should also be matched to the dowel size. For installation through the drill hole with dowels or impact anchors, the nominal diameter of the 9 mm HSS drill bit must be changed so that it is one millimetre larger than the dowel.

To avoid having to hold the support posts, we recommend providing additional support for the drainage channel when installing on the posts until the side rafters and inner rafters are installed. Only then will the substructure have free-standing stability, preventing the support posts from tilting forward or backward.

Technical data of the patio covering

- Material (profile): Aluminium (EN AW 6063-T6), powder-coated

- Colour (profile): Traffic white (RAL9016)

- Shape (profile): Square or rounded

- Material (covering): Polycarbonate (16mm double-skin sheet)

- Colour (covering): Opal

- Light transmission: 54%

- Roof width: from 4,06m to 12,06m

- Roof depth: from 2,00m to 5,00m

- Clearance height: max. 250cm

- Number of rafters: varies (width in meters + 1)

- Rafter spacing: 1 Metre

- Number of posts: varies (from 2 upto 5)

- Snow load zone: Snow load zone 1 (partly 2)

- Drainage: Yes, fully integrated in the post

- Corrosion resistance: Yes

- UV resistance (colour): Yes (10 year warranty)

- UV resistance (covering): Yes

Maintenance of the patio cover

The patio canopy is made exclusively of high-quality materials suitable for outdoor use. From corrosion-resistant aluminium and a UV- and weather-resistant white powder coating to the covering of lightweight double-walled sheets of opal polycarbonate, we do not skimp on the quality of the materials, so you do not have to worry about maintaining the canopy after installation.

The white profiles are slightly more sensitive to surface dirt, but this can be very easily removed with a high-pressure cleaner if necessary, so that the roofing shines again in new brilliance. If the patio is heated with an electric patio heater, lit with integrated lighting or equipped with an electric awning, no high-pressure cleaner should be used on these areas and they should be cleaned by hand in the tried-and-tested way. A soft cloth and clear water are suitable here. A mild soap solution can also help remove dust and dirt. Aggressive cleaning agents, scouring milk or hard scouring sponges, on the other hand, should never be used, as this can affect the satin finish of the aluminium profiles and twin-wall panels.

Besides cleaning the exterior, cleaning the gutter from time to time is also a task to ensure that rainwater can drain unhindered. Thanks to the leaf catcher, however, the effort is kept to a minimum and the gutter can be swept out and the leaf catcher cleared of leaves and small twigs that can accumulate over time.

When spraying the roof from above with a pressure washer or garden hose, always make sure the surface is firm and slip-resistant. However, it is not recommended to walk directly on the rafters or roofing. A wide plank to spread the load is well suited here. However, to protect the surfaces from scratches, it should not be placed directly on the rafters either, but should be protected with an anti-slip mat or similar as an intermediate layer.

- Additional Information

Additional Information

Product-ID W-PCO Delivery Time Dispatch within 8 - 12 weeks Material Aluminium (EN AW 6063-T6) Width No Depth No Covering Polycarbonate opal Glass thickness 16mm double-wall sheet Property Roofing for self-assembly Number of posts varies Number of rafters varies Snow load zone Snow load zone 1 Color White Color accuracy Production according to RAL color system RAL color code RAL9016 Color designation Traffic white - Reviews

- Attachments