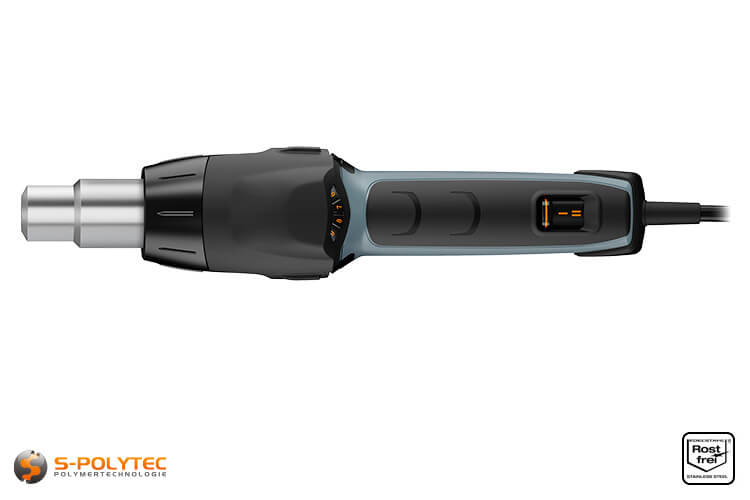

Hot-air welding unit STEINEL HG-2420E

The HG 2420 E rod blower is a hot-air unit from the STEINEL ® Professional-Line suitable for construction sites and is aimed at demanding users in a wide variety of trades as well as ambitious do-it-yourselfers with the highest quality requirements.

✓ Very long service life

✓ Powerful motor

✓ Ceramic heater hand-wound

✓ Suitable for construction sites

✓ In a practical case

The professional rod blower is easy to operate with multi-stage temperature and air volume regulation.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€179.00 / pc.

2,1500 kg / pc.

All prices include 19% VAT.

- Description

Hot air welding unit STEINEL® HG 2420 E

Enormous service life ✓ Ceramic heating ✓ Powerful motor ✓

The STEINEL® HG2420E hot-air welder from the Professional-Line is a professional unit suitable for construction sites and ideal for use by tradesmen and industry. The powerful brushed motor has a very long service life of 1,000 hours and the hand-wound ceramic heater can also be described as extremely durable with 800 hours of operation. The rod blower with a power of 2,200 watts allows a wide temperature range from 80°C to 650°C, which can be set in 9 stages using a selection wheel. The very reasonable price for a professional hot air welding tool contributes to the fact that this hand tool is not only aimed at the experienced user in a commercial context, but is also affordable for the do-it-yourselfer with the highest demands on functionality and quality.

Weighing just 610 grams (excl. cable), it is the lightest hot-air welder in the STEINEL® Professional-Line without compromising on functionality or the wide range of adjustment options. The compact rod blower HG2420E can be operated very easily with one hand on the top to regulate the temperature in nine stages. The air volume, too, can be adjusted in two stages on the handle using a robust, smooth-running slide switch. The low weight and slim design are a great advantage, especially if work is to be carried out over a longer period of time.

The HG2420E hot-air welder comes in a sturdy carrying case for STEINEL® rod units which, in addition to practical and safe storage of the welder, also offers plenty of space for optional professional nozzles, welding wires or shrink tubing.

-

Scope of delivery:

- 1 x STEINEL® hot air welding unit HG 2420 E

- 1 x transport case for rod instruments

TIP: Matching the rod blower HG2420E, we also offer separately available professional nozzles in various designs in our online shop.

Features of the STEINEL® HG 2420 E hot air welding unit

The hot-air blower STEINEL® HG2420E from the Professional-Line is a rod blower for professional use that can hardly be hidden behind the top model in the series. As a professional unit, the light, compact blower has a wide temperature range of 80°C to 650°C that can be regulated in 9 stages. The air volume can also be adjusted in two stages. In the first stage, 150l/min flow through the powerful motor past the ceramic heater. On the second stage the air flow rate is a whopping 400l/min. The smaller model thus also offers a wide range of setting options, which can be easily operated and read off on the top of the unit. Depending on the combination of the set temperature and air volume, the construction site suitable hot air welding device is suitable without hesitation for all typical areas of application, such as plastic welding, the removal of paints and varnishes or even the overlap welding of roofing membranes and vinyl floors.

The housing is made of robust ABS plastic, which is characterised by high impact resistance. The ergonomic shape and the low weight of 610 grams (without power cord) allows effortless working even during prolonged use. A thermal fuse protects the rod blower from thermal overload, so that the device cannot be overstrained by too intensive or improper use. Small non-slip feet, which are attached to the underside of the housing, ensure that the unit stands securely when laid down and prevent the blower from rolling away. The very well balanced centre of gravity, which is not only an advantage when working, also prevents the unit from tipping over on the exhaust pipe when laid down, thus scorching the ground.

As a professional hot air welding device, the HG2420E meets the strict requirements of the European safety standards and is marked with quality seals of VDE and GS (tested safety). The removable protective tube, which covers the stainless steel blow-out tube, also contributes to safety when using the hot air device, so that the risk of burns from contact with the heated blow-out tube is significantly minimised.

Just like the top model in the STEINEL® Professional-Line, the smaller model HG2420E also has the option of replacing the mains cable very easily. The 3-metre supply cable can thus be replaced by a longer mains cable if necessary to provide greater flexibility, e.g. when making long welds or welding roofing membranes and floor coverings. The unit is also equipped with a fine dust filter that is not only very easy to clean but, if necessary, can also be replaced with a new fine dust filter at any time thanks to the spare parts guarantee from STEINEL®. Unlike the flagship, however, the hand-wound ceramic heater is not pluggable, so replacement should only be carried out by Steinel's customer service. However, the manufacturer offers a first-class 48-hour repair service for the professional series of hot-air units.

Technical data of the STEINEL® HG 2420 E hot air welding unit

- Housing shape: Rod device

- Housing material: ABS

- Power: 2.200 W

- Temperature: 80°C - 650°C

- Air flow rate: 400 l/min

- Motor: Brush motor

- Heating: Ceramic

- Lifetime motor: 1.000 h.

- Lifetime of heating: 800 h.

- Cold stage: without

- Temperature setting: 9 levels

- Air volume setting: 2 levels

- Weight (without power cord): 0,610 kg

- Power cable: 3m H07

- Nozzle holder: Screwable professional nozzles

- Power cable interchangeable: Yes

- Heating pluggable: No

- Thermal fuse: Yes

- Suitable for construction: Yes

- Restart protection: No

- LCD-Display: No

- Residual heat display: No

- Save programmes: No

- LOC-Function: No

- Fine dust filter: Yes

Application examples for the hot air rod blower HG 2420 E

As a specialist dealer for cut-to-size plastic sheets, the first application we can think of for the rod blower STEINEL® HG2420E is, of course, welding plastics. Here, the compact lightweight is absolutely convincing. In combination with a screwable round nozzle in 5 mm diameter, plastic welding is very easy. Even if the temperature is not infinitely variable as with the HG2620E, the 9 steps still allow sufficiently fine gradations when choosing the perfect welding temperature for plastics such as PE-HD, PP-H, ABS or even PVC. With a high-speed welding shoe, which is attached to the round nozzle, welding of thermoplastics is made much easier, because the separate feeding of the welding wire, the welding wire is automatically tracked and heated exactly at the weld seam, which leads to an optimised welding result.

While roofing contractors or floor layers generally fall back on the larger model, the second largest rod blower from STEINEL® is also very often used in the trade. It is an extremely reliable device for continuous use and is often used in vehicle construction and for welding truck and trailer tarpaulins. The compact device is also often used for repair work on fittings and plastic body parts. In the painting trade, the hot-air unit is often used to remove old paints and varnishes before applying a new coat of paint. This saves time and also the use of solvents, which are usually hazardous to health. It is not uncommon for an angled flat nozzle to be screwed on in order to enable more targeted heating over a larger area and to be able to remove the paint with a scraper or spatula.

The high-quality hot-air blower is also used in orthopaedics to adapt prostheses to the wearer's needs by heating them up. The situation is similar in the fitting and manufacture of sports equipment, which is individually adapted to the athlete by heating. Although this method is mainly used in professional competitive sports, the final adaptation of the shape is also quite common for hard shells of high-quality roller skates, inline skates or even canoes. Repairing plastic boats and playground equipment made of plastic by welding cracks and fractures are further areas of application where a conventional hot-air dryer usually quickly reaches its limits.

Of course, the hot air welding device is also suitable for shrinking cable connections, terminals, wall bushings or for repairing damaged cable sheathing with a shrink hose. Likewise, hot-forming plastic pipes, plastic rods or smaller plastic sheets that need to be bent around a radius is a common job that can be carried out with the professional tool from STEINEL® without any problems. Depending on the specific application, professional nozzles in a wide variety of designs can not only make the job much easier but also lead to an improved result.

-

Recommended nozzles for the hot air welding unit HG 2420 E:

- Round jets 5mm: As holder for the quick welding shoe or for spot heating

- Speed welding shoe: With welding wire feed to simplify plastic welding

- Angular flat nozzles: for surface heating during thermoforming or colour removal

- Reflex dip: for cable shrinking and hot forming e.g. plastic tubes and rods

Warning: Only screw-on nozzles can be used as professional equipment. Attachable nozzles, on the other hand, are not suitable for the rod blower.

- Additional Information

Additional Information

Product-ID ST-HG2420E-K Delivery Time Dispatch within 2-3 working days EAN/GTIN 4007841008284 Weight 2.1500 Power 2.200 Voltage 230 Power supply 230V - Reviews

- Attachments